強力な金属探知機により、エンドユーザーにさらなる安全性を

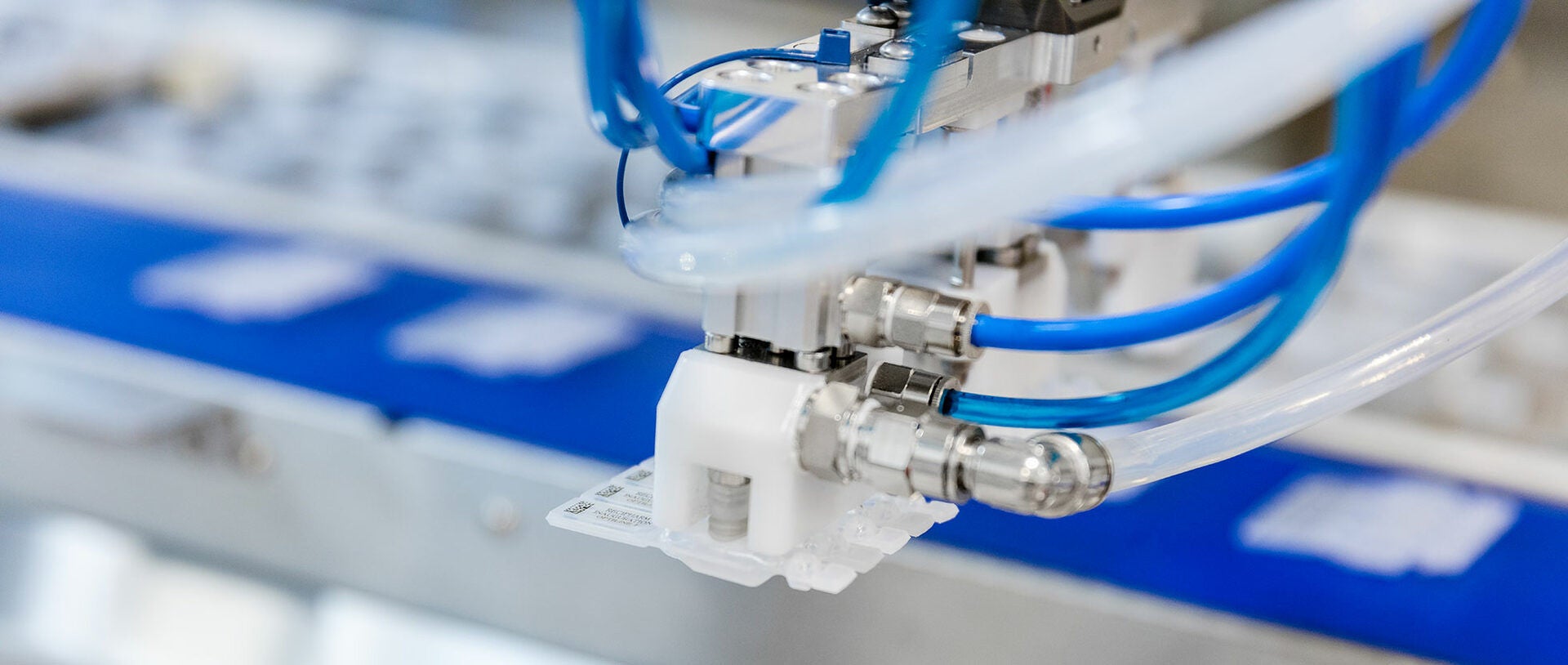

製品に含まれる金属粒子が検出されずに最終消費者に届いてしまった場合、不愉快な結果をもたらす可能性があります。怪我をする危険性はもちろんのこと、あなたのビジネスにも影を落とすことになります。製品の純度を信頼できるように、MULTIVACの金属検出機は最も厳しい条件下でも最小の粒子を確実に検出し、現在の包装ラインを分析、個別にアドバイスします。お客様の検査タスクに合わせ、最小限のスペースで最適なソリューションの提案が可能です。信頼性、安定した検査品質、再現性を重視し、製品・包装・工程の信頼性を最大限に高めます。消費電力が少なく、摩耗が少ないため、最適な効率と迅速な投資回収を実現できるでしょう。

金属探知機による生産と品質管理の安全性

当社の金属探知システムは金属異物を検出します。鉄、ステンレス、鋼、アルミニウム、銅、真鍮などの非鉄金属のいずれであってもMULTIVAC検査ユニットは異物の確実な検知を可能にします。最も重い条件下でも、検知器は正確かつ確実に機能します。

MULTIVACは個性を最優先し、お客様の包装プロセスに最適に統合できるようプロジェクトをサポートします。計量器など他の検査装置とのユニークな組み合わせや、不良パックの追加排出など、当社は適切なソリューションを見つけることができます。

成功事例

Complex pack design for disposable razors

Defi nition of the tasks for MULTIVAC: Absolute adherence to delivery date, the integration of existing line components and above all the guarantee, that the new pack for the Xtreme 3 disposable razor would not be any different from the products, which were already well known in the market.

Defi nition of the tasks for MULTIVAC: Absolute adherence to delivery date, the integration of existing line components and above all the guarantee, that the new pack for the Xtreme 3 disposable razor would not be any different from the products, which were already well known in the market.

Mehr erfahren

Attractive solutions for full-wrap labelling of packs

MULTIVAC Marking & Inspection has continually expanded its range of conveyor belt labellers in recent years. The spectrum now includes a wide range of solutions for many different labelling requirements and output categories – from the simple BASELINE conveyor belt labellers to 2-track labelling systems with up to ten label dispensers.

MULTIVAC Marking & Inspection has continually expanded its range of conveyor belt labellers in recent years. The spectrum now includes a wide range of solutions for many different labelling requirements and output categories – from the simple BASELINE conveyor belt labellers to 2-track labelling systems with up to ten label dispensers.

Mehr erfahren

Fresh seafood: processed and packed immediately

A coveted location directly by the fishing port of Nanfang-ao in Yilan County, Taiwan. Seafood in its freshest form, creative recipes and the highest quality, as well as technological standards. This is how Cheer Foods, market leader in the domestic fish processing industry, likes to be described. More than 2,000 tons of its specialities are exported to China, Hong Kong, South East Asia and America by the innovative and traditional family company.

A coveted location directly by the fishing port of Nanfang-ao in Yilan County, Taiwan. Seafood in its freshest form, creative recipes and the highest quality, as well as technological standards. This is how Cheer Foods, market leader in the domestic fish processing industry, likes to be described. More than 2,000 tons of its specialities are exported to China, Hong Kong, South East Asia and America by the innovative and traditional family company.

Mehr erfahren

Poultry products of the highest quality and multiple package variations

Bell & Evans in Fredericksburg, Pennsylvania processes poultry products of the highest quality. The renowned company with a long tradition is not known for compromising when it comes to packing its products. MULTIVAC thermoform packaging machines have been successfully in use at the company for a number of years to produce high-quality FormShrink® packs. Over time, additional packaging machines have been added in succession – among them five complex packaging lines, which were installed at the same time in 2015, to produce MultiFresh™ packs.

Bell & Evans in Fredericksburg, Pennsylvania processes poultry products of the highest quality. The renowned company with a long tradition is not known for compromising when it comes to packing its products. MULTIVAC thermoform packaging machines have been successfully in use at the company for a number of years to produce high-quality FormShrink® packs. Over time, additional packaging machines have been added in succession – among them five complex packaging lines, which were installed at the same time in 2015, to produce MultiFresh™ packs.

Mehr erfahren

For maximum security - Product monitoring in the packaging procedure

Thanks to a wide range of inspection solutions, capable of seamelss integrationd into the packaging line, automated quality control can be performed very reliably, even for high-output applications.

Thanks to a wide range of inspection solutions, capable of seamelss integrationd into the packaging line, automated quality control can be performed very reliably, even for high-output applications.

Mehr erfahren

MULTIVAC Tray Carrier as a solution for packing in small series of batches

Comprehensive quality control

Comprehensive quality control

Mehr erfahren

How are bundled plastic ampoules packed efficiently and fully automatically in folding cartons?

In order to react flexibly in future to customer requirements, Recipharm commissioned the MCP project team at MULTIVAC with the task of developing an upgradable solution for the automated bundling and cartonning of eyedrop ampoules with an additional pack leaflet.

In order to react flexibly in future to customer requirements, Recipharm commissioned the MCP project team at MULTIVAC with the task of developing an upgradable solution for the automated bundling and cartonning of eyedrop ampoules with an additional pack leaflet.

Mehr erfahren

Automated production of combi packs

Packaging procedures with a high degree of complexity are often used to produce combi packs for pharmaceutical products. Infeed systems, which have to be tailored precisely to the particular components, and also integrated into the packaging line, are required for the automated infeed and loading of the various product components. This means the top priority is the precise and secure positioning of the product components, which are usually very small.

Packaging procedures with a high degree of complexity are often used to produce combi packs for pharmaceutical products. Infeed systems, which have to be tailored precisely to the particular components, and also integrated into the packaging line, are required for the automated infeed and loading of the various product components. This means the top priority is the precise and secure positioning of the product components, which are usually very small.

Mehr erfahren

Success has a name

The modular conveyor belt labellers of the L 320 series from MULTIVAC Marking & Inspection offer the highest level of flexibility and precision in the labelling of cylindrical and oval products, shaped bottles, glasses and pots. Just such a model has recently been put into operation at Dr. August Wolff GmbH & Co. KG Arzneimittel for labelling the Linola products among others.

The modular conveyor belt labellers of the L 320 series from MULTIVAC Marking & Inspection offer the highest level of flexibility and precision in the labelling of cylindrical and oval products, shaped bottles, glasses and pots. Just such a model has recently been put into operation at Dr. August Wolff GmbH & Co. KG Arzneimittel for labelling the Linola products among others.

Mehr erfahren

Secure packaging of wound contact products

With its patented Debrisoft® wound contact products, Lohmann & Rauscher offers an holistic concept for all aspects of therapeutic wound cleaning, and one which is painless for patients in its application. For these products, the packs have to be capable of being sterilised with ethylene oxide. In order to ensure a high level of pack security is achieved, particular emphasis was placed during the development of the packaging solution on the quality of the seal seam, where an even distribution of sealing pressure and temperature during the sealing process is absolutely critical.

With its patented Debrisoft® wound contact products, Lohmann & Rauscher offers an holistic concept for all aspects of therapeutic wound cleaning, and one which is painless for patients in its application. For these products, the packs have to be capable of being sterilised with ethylene oxide. In order to ensure a high level of pack security is achieved, particular emphasis was placed during the development of the packaging solution on the quality of the seal seam, where an even distribution of sealing pressure and temperature during the sealing process is absolutely critical.

Mehr erfahren

MULTIVAC solutions for secondary packaging – highly efficient and reliable to the end of the line

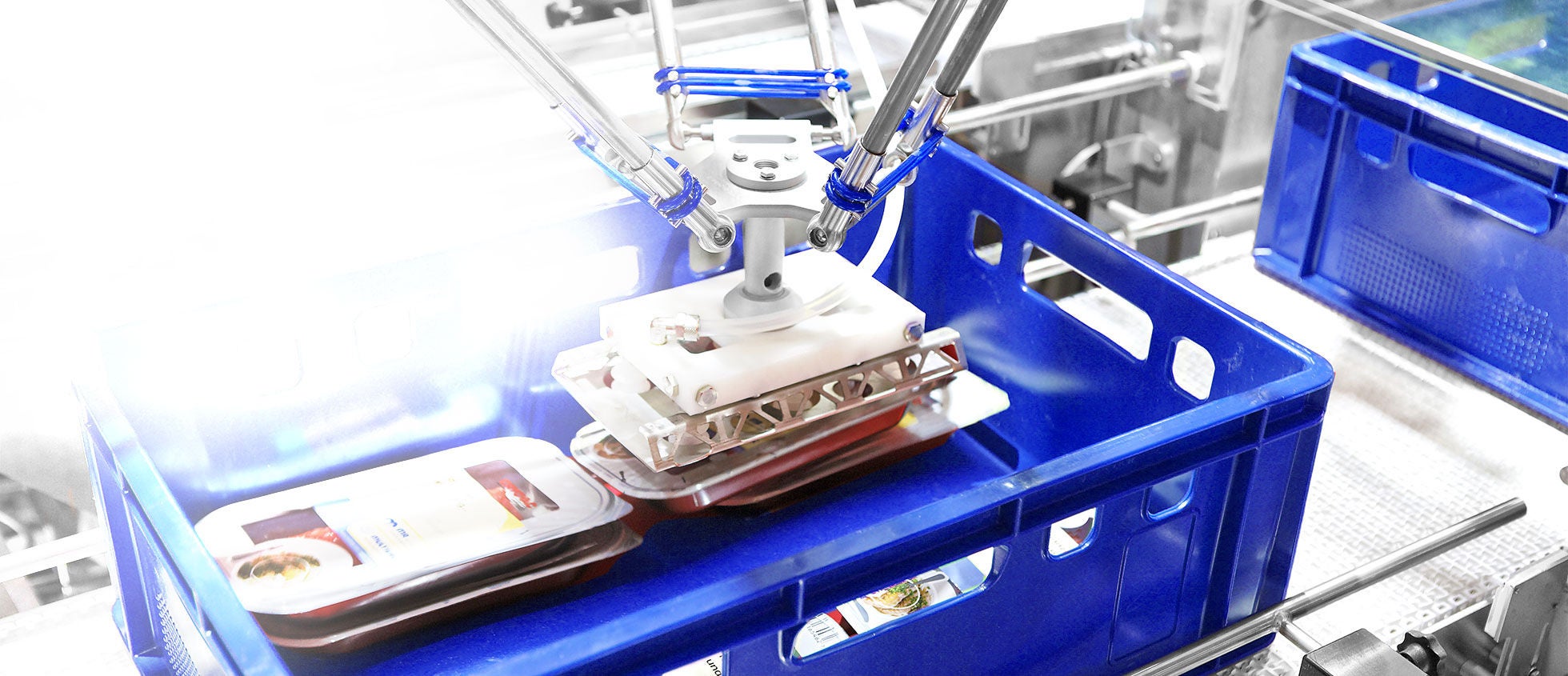

When it comes to loading packs into boxes or crates, and grouping or converging packs, MULTIVAC offers a wide range of end-of-line solutions, which are very flexible to use and which are individually designed to customer requirements. They can be used to automate quickly and precisely a wide range of tasks for a variety of products, pack formats, weights, and cycle times. They are also very reliable in their targeted ejection of empty or reject packs, and this contributes significantly to increasing process reliability and line efficiency.

When it comes to loading packs into boxes or crates, and grouping or converging packs, MULTIVAC offers a wide range of end-of-line solutions, which are very flexible to use and which are individually designed to customer requirements. They can be used to automate quickly and precisely a wide range of tasks for a variety of products, pack formats, weights, and cycle times. They are also very reliable in their targeted ejection of empty or reject packs, and this contributes significantly to increasing process reliability and line efficiency.

Mehr erfahren

Maximum pack attractiveness with Full Wrap labelling

Full wrap labels offer a broad range of competitive advantages in comparison to other labelling solutions. In addition to their function as an information medium, they are increasingly becoming an important design element of retail packs. This way, they help the brand owners to increase the differentiation of the product at the Point of Sale and to offer further value to the consumer.

Full wrap labels offer a broad range of competitive advantages in comparison to other labelling solutions. In addition to their function as an information medium, they are increasingly becoming an important design element of retail packs. This way, they help the brand owners to increase the differentiation of the product at the Point of Sale and to offer further value to the consumer.

Mehr erfahren

Reliable quality control

Thanks to visual inspection systems, quality control can be automated within the packaging procedure. These systems offer added value, particularly for food-processing businesses, since all the packs in a batch can be checked seamlessly instead of random sampling. Bell Schweiz AG with its headquarters in Basel is currently evaluating a pilot inspection system with a view to major investment. Pack aktuell* spoke to the person responsible for the project.

Thanks to visual inspection systems, quality control can be automated within the packaging procedure. These systems offer added value, particularly for food-processing businesses, since all the packs in a batch can be checked seamlessly instead of random sampling. Bell Schweiz AG with its headquarters in Basel is currently evaluating a pilot inspection system with a view to major investment. Pack aktuell* spoke to the person responsible for the project.

Mehr erfahren

Cheese attractively packed

Vergeer Holland is one of the largest and most innovative cheese processors in the world. The company has grown in recent years into a flourishing business with 550 employees, and today packs around 60 million kilos of cheese per year. The company does not produce cheese, but specializes in maturing, slicing and packaging hard cheese. Its most important customers are retailing companies. When it comes to the packing and labelling of its diverse cheese products, Vergeer Holland relies on solutions from MULTIVAC: a total of 25 packaging machines and over 50 labellers from MULTIVAC are used within the company.

Vergeer Holland is one of the largest and most innovative cheese processors in the world. The company has grown in recent years into a flourishing business with 550 employees, and today packs around 60 million kilos of cheese per year. The company does not produce cheese, but specializes in maturing, slicing and packaging hard cheese. Its most important customers are retailing companies. When it comes to the packing and labelling of its diverse cheese products, Vergeer Holland relies on solutions from MULTIVAC: a total of 25 packaging machines and over 50 labellers from MULTIVAC are used within the company.

Mehr erfahren

Automation in meat processing offers a wide range of benefits

The food industry is booming. An ever increasing number of fresh and processed food products, snacks, ready meals, and convenience products have to be manufactured and packed. But it has become more difficult to find suitable or qualified staff. There is currently an acute lack of personnel in the meat processing sector. At the same time, hygiene and quality requirements are increasing. Automation solutions provide one way out of the dilemma. However, robots have been used to a very limited extent in the meat industry up to now.

The food industry is booming. An ever increasing number of fresh and processed food products, snacks, ready meals, and convenience products have to be manufactured and packed. But it has become more difficult to find suitable or qualified staff. There is currently an acute lack of personnel in the meat processing sector. At the same time, hygiene and quality requirements are increasing. Automation solutions provide one way out of the dilemma. However, robots have been used to a very limited extent in the meat industry up to now.

Mehr erfahren

“MULTIVAC is a real partner for us.”

Cater Food mainly processes pork and beef in both premium and bio grades. Since the two existing machines at the Herrup site were barely able to cope with the constantly rising production quantities, the Danish company, which has seen strong growth in recent times, decided to invest in a R 515 thermoforming packaging machine, which was specially developed by MULTIVAC to meet the demands of the fresh meat industry. The decision was also made to purchase a traysealer for the factory in Mors, so that the company could serve the strong demand for larger portions of minced meat in modern MAP packs. Minced meat is actually one of the company’s biggest selling products.

Cater Food mainly processes pork and beef in both premium and bio grades. Since the two existing machines at the Herrup site were barely able to cope with the constantly rising production quantities, the Danish company, which has seen strong growth in recent times, decided to invest in a R 515 thermoforming packaging machine, which was specially developed by MULTIVAC to meet the demands of the fresh meat industry. The decision was also made to purchase a traysealer for the factory in Mors, so that the company could serve the strong demand for larger portions of minced meat in modern MAP packs. Minced meat is actually one of the company’s biggest selling products.

Mehr erfahren

Automation solutions for the bakery product industry

The bread and bakery product industry finds itself in a far-reaching transition. Cost pressure, product diversity in the market, altered consumer habits, and hygiene regulations require companies not only to adapt their product range but also to optimise their production processes. One important approach as regards packaging are solutions with a high degree of automation.

The bread and bakery product industry finds itself in a far-reaching transition. Cost pressure, product diversity in the market, altered consumer habits, and hygiene regulations require companies not only to adapt their product range but also to optimise their production processes. One important approach as regards packaging are solutions with a high degree of automation.

Mehr erfahren

Focus on packaging diversity

The Turkish fish processor, SASTAS, which is located in the city of Samsun, has invested in a R 245 thermoforming packaging machine. This machine was intended primarily for packing marinated fish fillets in pure sunflower oil.

The Turkish fish processor, SASTAS, which is located in the city of Samsun, has invested in a R 245 thermoforming packaging machine. This machine was intended primarily for packing marinated fish fillets in pure sunflower oil.

Mehr erfahren

Halal meat and sausage products in many varieties

Burger patties, pizza toppings, sausage and sausage products as well as tasty snacks and convenience foods are the core business of Fettayleh Foods. Since it was first founded, the Australian family business has developed into a leading supplier of halal food and it now exports its high-quality products all over the world. A traysealer had previously been handling the packaging procedure, but the company’s attention was drawn to MULTIVAC’s R 105 MF thermoforming packaging machine at Anuga FoodTec 2015 and they have seen benefits from its use ever since.

Burger patties, pizza toppings, sausage and sausage products as well as tasty snacks and convenience foods are the core business of Fettayleh Foods. Since it was first founded, the Australian family business has developed into a leading supplier of halal food and it now exports its high-quality products all over the world. A traysealer had previously been handling the packaging procedure, but the company’s attention was drawn to MULTIVAC’s R 105 MF thermoforming packaging machine at Anuga FoodTec 2015 and they have seen benefits from its use ever since.

Mehr erfahren

Koninklijke Vezet places its trust in labelling solutions from MULTIVAC

Fresh food products, together with quality, convenience, and sustainability, are of increasing importance in the everyday lives of consumers. Koninklijke Vezet has developed into a fruit and vegetable specialist, which meets all these requirements. Companies which want to survive in the growing but very challenging fresh food market must also guarantee fast deliveries and the right packaging. Labelling is also an important part of the packaging procedure: labels not only have an effect on the appearance of the packs, they also contain important information for consumer protection.

Fresh food products, together with quality, convenience, and sustainability, are of increasing importance in the everyday lives of consumers. Koninklijke Vezet has developed into a fruit and vegetable specialist, which meets all these requirements. Companies which want to survive in the growing but very challenging fresh food market must also guarantee fast deliveries and the right packaging. Labelling is also an important part of the packaging procedure: labels not only have an effect on the appearance of the packs, they also contain important information for consumer protection.

Mehr erfahren

Maintaining freshness with MAP packs

Japanese consumers prefer fresh, appetising and high-quality food products, which are marketed in attractive packs. The products are generally sold in many different variations and produced in small batch sizes. This means a number of challenges have to be overcome at production sites, such as limited production areas and sudden reductions in the economically active population.

Japanese consumers prefer fresh, appetising and high-quality food products, which are marketed in attractive packs. The products are generally sold in many different variations and produced in small batch sizes. This means a number of challenges have to be overcome at production sites, such as limited production areas and sudden reductions in the economically active population.

Mehr erfahren

MultiFresh™ packs with full-wrap labelling increase the attractiveness at the point of sale

With its deep, clear and cold fjords, Norway is a paradise for salmon and salmon farms alike. Best conditions therefore for Seafood Farmers of Norway AS, which was founded in 1986, and its parent company the HOFSETH Group, which processes the freshly caught fish and exports most of it abroad. In order to increase the attractiveness of the fish products at the point of sale, the company in Valderøy recently invested in a thermoforming packaging machine for producing high-quality vacuum skin packs and in a labelling solution for the D labelling of the packs.

With its deep, clear and cold fjords, Norway is a paradise for salmon and salmon farms alike. Best conditions therefore for Seafood Farmers of Norway AS, which was founded in 1986, and its parent company the HOFSETH Group, which processes the freshly caught fish and exports most of it abroad. In order to increase the attractiveness of the fish products at the point of sale, the company in Valderøy recently invested in a thermoforming packaging machine for producing high-quality vacuum skin packs and in a labelling solution for the D labelling of the packs.

Mehr erfahren

Different packaging concepts and methods for preserving meat quality

There are different packaging concepts depending on the particular product and the processing stage within the added value chain. This means that different technology and packaging materials are required, when transport or maturation packs for example are being produced, from those required for retail packs for the end consumer. In addition to the high demands placed on hygiene and functionality, one of the most important objectives of a pack is to provide extended shelf life for the product.

There are different packaging concepts depending on the particular product and the processing stage within the added value chain. This means that different technology and packaging materials are required, when transport or maturation packs for example are being produced, from those required for retail packs for the end consumer. In addition to the high demands placed on hygiene and functionality, one of the most important objectives of a pack is to provide extended shelf life for the product.

Mehr erfahren

Automatic loading of sausage and meat products into the packaging machine

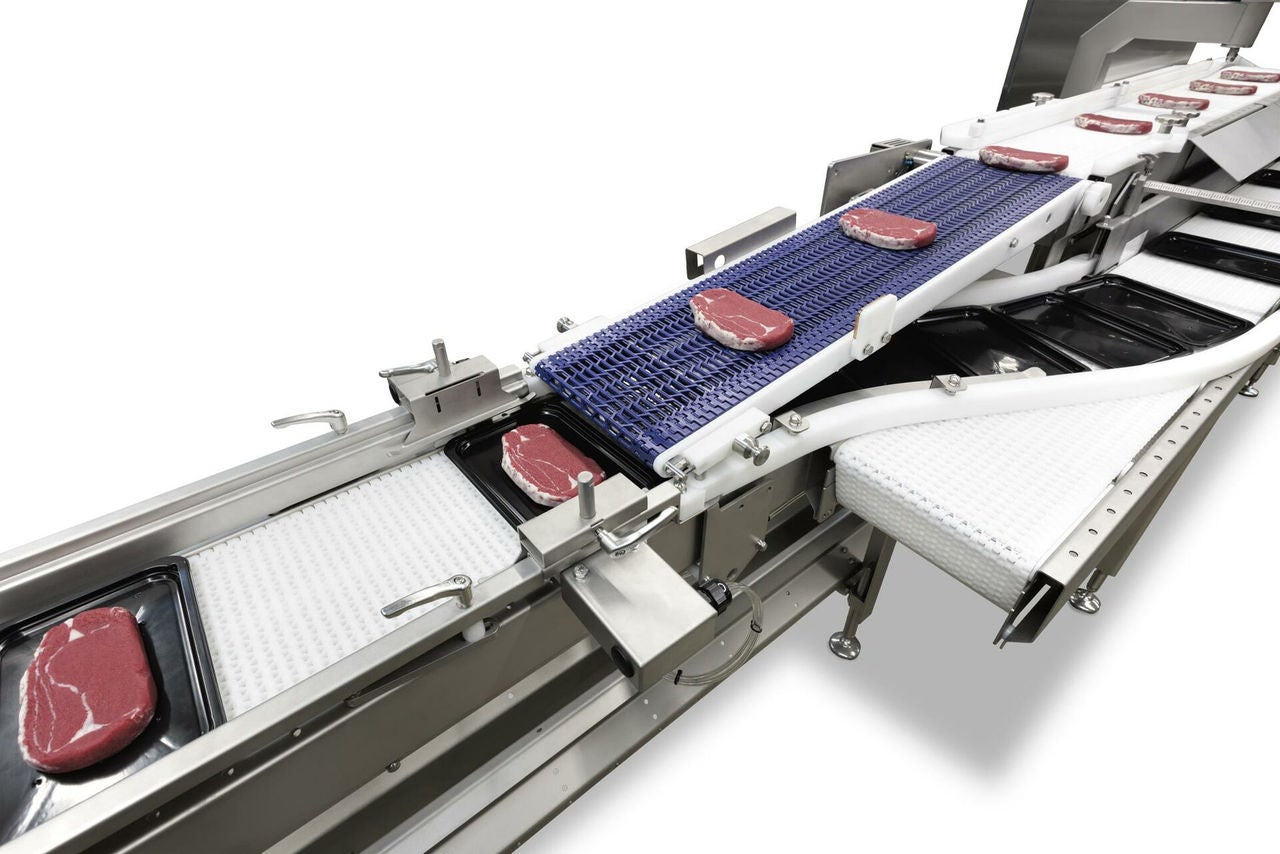

Today practically every stage in the processing and packing of meat and sausage products can be automated. But different products such as sliced meats, sausages or fresh meat require individual solutions. In the following article there are descriptions of the possible options for feeding and loading products efficiently and gently into the pack cavities.

Today practically every stage in the processing and packing of meat and sausage products can be automated. But different products such as sliced meats, sausages or fresh meat require individual solutions. In the following article there are descriptions of the possible options for feeding and loading products efficiently and gently into the pack cavities.

Mehr erfahren

Perfect slicing results for fresh meat and processed products

Precise weight control in the portioning and slicing of meat or sausage products is one of the standard requirements in industrialised processing of fresh food. The slicing quality of the finished product is influenced significantly by the tempering and forming of the raw product, as well as by the slicing technology used. In this article we have compiled those aspects, which need to be taken into account with slicing, depending on the particular product and the outline conditions.

Precise weight control in the portioning and slicing of meat or sausage products is one of the standard requirements in industrialised processing of fresh food. The slicing quality of the finished product is influenced significantly by the tempering and forming of the raw product, as well as by the slicing technology used. In this article we have compiled those aspects, which need to be taken into account with slicing, depending on the particular product and the outline conditions.

Mehr erfahren

“A holistic approach to retail thinking, management, and processes”

In Germany food still arrives at the consumer in the classic way via traditional physical retailing. Only one percent of significant market volume is handled online. But the market potential is huge - as are the challenges presented to online retailers, particularly as regards the logistics. We spoke to Dr. Reinhard Grandke, Head of the German Agricultural Society (DLG) about the challenges and opportunities for digitalisation in food retailing.

In Germany food still arrives at the consumer in the classic way via traditional physical retailing. Only one percent of significant market volume is handled online. But the market potential is huge - as are the challenges presented to online retailers, particularly as regards the logistics. We spoke to Dr. Reinhard Grandke, Head of the German Agricultural Society (DLG) about the challenges and opportunities for digitalisation in food retailing.

Mehr erfahren

Beef jerky in attractive aluminium packs

Dried meat is one of the most popular snacks in China. But jerky has now also become one of the top sellers in the USA, and even recently in Germany. The market for the spicy, long-life strips and pieces of beef, duck, and ostrich meat is booming worldwide. The sales figures in the snacks segment are strongly driven by marketing. The Chinese company, Zhangfei Beef, recognized this trend at an early stage and now presents its high-quality beef snacks at the point of sale in attractive aluminium packs.

Dried meat is one of the most popular snacks in China. But jerky has now also become one of the top sellers in the USA, and even recently in Germany. The market for the spicy, long-life strips and pieces of beef, duck, and ostrich meat is booming worldwide. The sales figures in the snacks segment are strongly driven by marketing. The Chinese company, Zhangfei Beef, recognized this trend at an early stage and now presents its high-quality beef snacks at the point of sale in attractive aluminium packs.

Mehr erfahren

Fresh meat for the chill cabinet packed on site as required

Last year MULTIVAC equipped each of the 43 retail outlets of the Swedish supermarket chain, Bergendahls/City Gross, with a R 105 MF for packing fresh meat in vacuum skin packs. The compact thermoforming packaging machines support Bergendahls in optimising its internal logistics, and they make a significant contribution to reducing food wastage. The attractiveness of the packs for the consumer has also been increased significantly.

Last year MULTIVAC equipped each of the 43 retail outlets of the Swedish supermarket chain, Bergendahls/City Gross, with a R 105 MF for packing fresh meat in vacuum skin packs. The compact thermoforming packaging machines support Bergendahls in optimising its internal logistics, and they make a significant contribution to reducing food wastage. The attractiveness of the packs for the consumer has also been increased significantly.

Mehr erfahren

"The entry into thermoforming packing was an important, strategic step for us."

Knorrevången Slakt AB in the Swedish town of Gilmåkra is one of the ten largest slaughtering companies in the country. The slaughtered animals are supplied either whole or in sections to the wholesale trade, but a large part of the fresh meat is also supplied pre-portioned to processing companies. There it is further processed into a wide range of sausage, ham, and meat products. Thanks to the purchase of a compact thermoforming packaging machine, Knorrevången has now also been able to open up the B2C market.

Knorrevången Slakt AB in the Swedish town of Gilmåkra is one of the ten largest slaughtering companies in the country. The slaughtered animals are supplied either whole or in sections to the wholesale trade, but a large part of the fresh meat is also supplied pre-portioned to processing companies. There it is further processed into a wide range of sausage, ham, and meat products. Thanks to the purchase of a compact thermoforming packaging machine, Knorrevången has now also been able to open up the B2C market.

Mehr erfahren

Packing sustainably

The new Packaging Legislation has been in force in Germany since the start of 2019. Among other things, it lays down challenging quotas for the recycling of materials and the reusability of packs. The introduction of a functioning closed-loop system for the packaging industry, as well as establishing that plastics are a reusable and therefore valuable resource, are important steps in the right direction. In parallel with this, the packaging industry is also driving forward the development of packs made from alternative materials. In addition to the introduction of a closed-loop system for plastics, the reduction in the consumption of plastics in the production of packs also represents another sensible approach to the sustainable development of the packaging industry.

The new Packaging Legislation has been in force in Germany since the start of 2019. Among other things, it lays down challenging quotas for the recycling of materials and the reusability of packs. The introduction of a functioning closed-loop system for the packaging industry, as well as establishing that plastics are a reusable and therefore valuable resource, are important steps in the right direction. In parallel with this, the packaging industry is also driving forward the development of packs made from alternative materials. In addition to the introduction of a closed-loop system for plastics, the reduction in the consumption of plastics in the production of packs also represents another sensible approach to the sustainable development of the packaging industry.

Mehr erfahren

“Tradition is always based on innovation”

For more than a century Albert Spiess AG has been committed to this philosophy. In addition to classics such as "Bündnerfleisch" air-dried meat, dry-cured ham and raw sausage specialities, the company's product range also includes pioneering innovations such as "my ENERGY" snacks.

For more than a century Albert Spiess AG has been committed to this philosophy. In addition to classics such as "Bündnerfleisch" air-dried meat, dry-cured ham and raw sausage specialities, the company's product range also includes pioneering innovations such as "my ENERGY" snacks.

Mehr erfahren

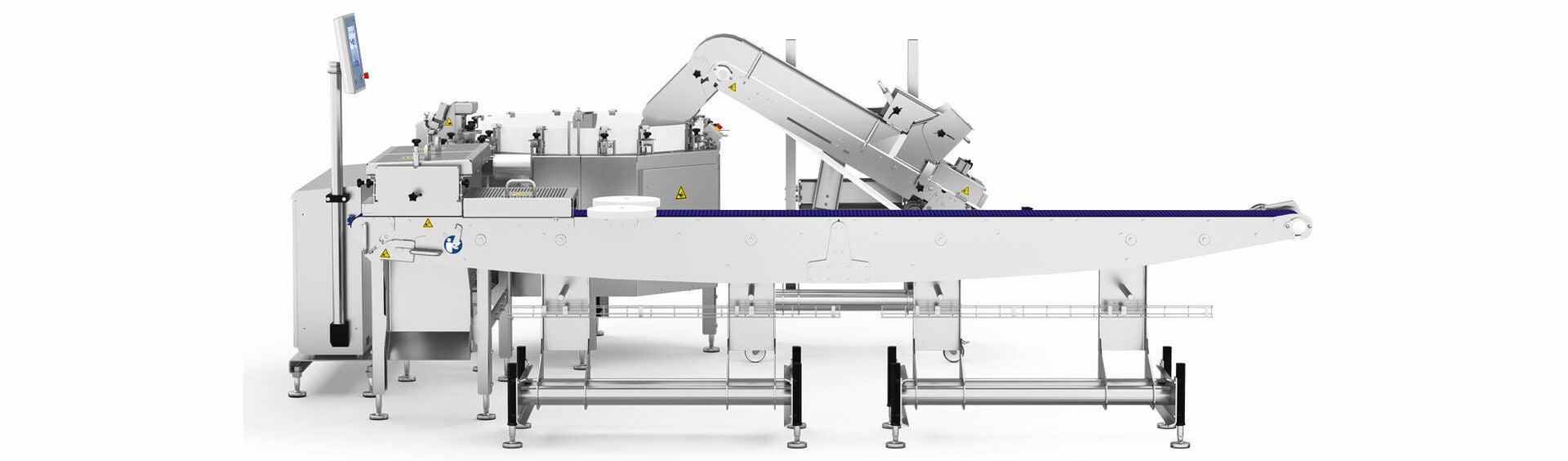

Use automation to master modern challenges in the food industry

Intelligently used automation solutions can make a major contribution in the food industry to designing an efficient, hygienic, and cost-effective packaging process. Automation is particularly worthwhile for product loading, even if this process represents a real challenge for some applications due to the diverse nature of the products. This article will throw light on those systems, which are available for the most common tasks in this sector.

Intelligently used automation solutions can make a major contribution in the food industry to designing an efficient, hygienic, and cost-effective packaging process. Automation is particularly worthwhile for product loading, even if this process represents a real challenge for some applications due to the diverse nature of the products. This article will throw light on those systems, which are available for the most common tasks in this sector.

Mehr erfahren

Labelling of dairy products

The range of dairy products is very large - it extends from hard cheese, semi-hard sliced cheese or soft cheese through to butter and cream cheese and right up to liquid or creamy products such as milk, whipped cream, and yogurt. In this article you will learn how the labelling process for the different product groups can be performed as reliably, efficiently, and cost-effectively as possible.

The range of dairy products is very large - it extends from hard cheese, semi-hard sliced cheese or soft cheese through to butter and cream cheese and right up to liquid or creamy products such as milk, whipped cream, and yogurt. In this article you will learn how the labelling process for the different product groups can be performed as reliably, efficiently, and cost-effectively as possible.

Mehr erfahren

Sustainable packaging concepts for sliced cheese

Thanks to the driving force of the EU's Plastics Strategy and new packaging legislation, the issue of sustainability is now gaining increasing importance in the packing of dairy products. At the same time the strict hygiene regulations must however continue to be observed, while also maintaining the maximum shelf life for the food products. Innovative packaging concepts can help to master the difficult balancing act between sustainability, product protection, and retaining quality.

Thanks to the driving force of the EU's Plastics Strategy and new packaging legislation, the issue of sustainability is now gaining increasing importance in the packing of dairy products. At the same time the strict hygiene regulations must however continue to be observed, while also maintaining the maximum shelf life for the food products. Innovative packaging concepts can help to master the difficult balancing act between sustainability, product protection, and retaining quality.

Mehr erfahren

Optimum slicing quality and weight accuracy when producing cheese slices

Today a large variety of sliced cheese is sold in chill cabinets in every supermarket. The different sorts, such as Appenzeller, Edam, Gouda, Leerdammer, or Tilsiter are either packed as shingled or wafer-thin slices, which are folded and presented attractively in the pack. While also maintaining the highest hygienic standards, producers today must operate with the maximum efficiency, flexibility, weight accuracy, and yield, if they are to remain competitive in the market. But how can these requirements be met? And what in particular must be taken into account when slicing cheese?

Today a large variety of sliced cheese is sold in chill cabinets in every supermarket. The different sorts, such as Appenzeller, Edam, Gouda, Leerdammer, or Tilsiter are either packed as shingled or wafer-thin slices, which are folded and presented attractively in the pack. While also maintaining the highest hygienic standards, producers today must operate with the maximum efficiency, flexibility, weight accuracy, and yield, if they are to remain competitive in the market. But how can these requirements be met? And what in particular must be taken into account when slicing cheese?

Mehr erfahren

Valve sets packed efficiently and reliably

Science and technological progress, combined with inspiration and

determination - this is the basis of Boston Scientific's success.

Science and technological progress, combined with inspiration and

determination - this is the basis of Boston Scientific's success.

Mehr erfahren

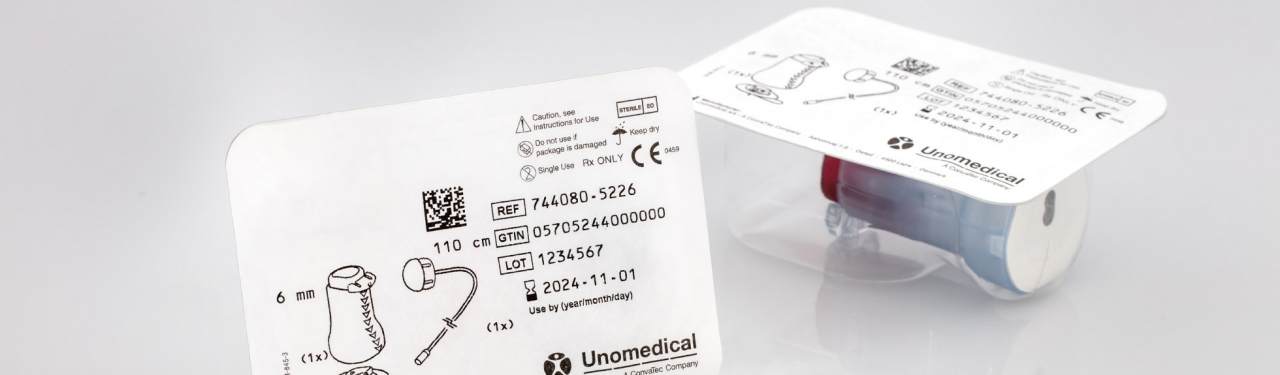

Highly complex line for the packing of sterile products for infusion therapy

ConvaTec and MULTIVAC can look back over 20 years of successful cooperation.

ConvaTec and MULTIVAC can look back over 20 years of successful cooperation.

Mehr erfahren

Automated label and print inspection in the food industry

Rising demands in food labelling increase the complexity of information that has to be printed on labels. As the throughput of packaging lines continues to increase, it is no longer possible for the human eye to inspect label print thoroughly. Although present legislation does not yet stipulate the use of visual inspection systems for checking labels, investment in automatic inspection systems can be very beneficial for many reasons.

Rising demands in food labelling increase the complexity of information that has to be printed on labels. As the throughput of packaging lines continues to increase, it is no longer possible for the human eye to inspect label print thoroughly. Although present legislation does not yet stipulate the use of visual inspection systems for checking labels, investment in automatic inspection systems can be very beneficial for many reasons.

Mehr erfahren

Full wrap labelling for maximum pack attractiveness at the POS

Full wrap labels, which enclose all four sides of a pack like a banderole, feature a whole range of competitive advantages over other solutions for labelling and marking. In addition to their function as information carriers, full wrap labels are today also an essential design feature for increasing the appeal of packs on the shelf. They support manufacturers in optimal presentation of their brand and offer consumers real added value.

Full wrap labels, which enclose all four sides of a pack like a banderole, feature a whole range of competitive advantages over other solutions for labelling and marking. In addition to their function as information carriers, full wrap labels are today also an essential design feature for increasing the appeal of packs on the shelf. They support manufacturers in optimal presentation of their brand and offer consumers real added value.

Mehr erfahren

Digital printing systems fulfil challenging pack marking requirements

The UDI Directive applies to all companies, which manufacture medical products or bring these into circulation. From 25 April 2020 all products of Class III together with implants must be marked with a distinct and unique identification number, and this applies from May 2023 to products of Class IIa and IIb, as well as from 2025 to products of Class I. This distinct product identification is allocated by various bodies - these are currently GS1, HIBCC and ICCBBA. The products together with their master data and a so-called Basic UDI are registered in a new, central database (Eudamed) covering all of Europe.

The UDI Directive applies to all companies, which manufacture medical products or bring these into circulation. From 25 April 2020 all products of Class III together with implants must be marked with a distinct and unique identification number, and this applies from May 2023 to products of Class IIa and IIb, as well as from 2025 to products of Class I. This distinct product identification is allocated by various bodies - these are currently GS1, HIBCC and ICCBBA. The products together with their master data and a so-called Basic UDI are registered in a new, central database (Eudamed) covering all of Europe.

Mehr erfahren

Carrier concepts as an important building block for automation in the packaging process

Today, packaging machines in the medical and pharmaceutical industries are generally a central component of an increasingly complex system solution, which is invariably complemented by customised conveyor and infeed systems, handling modules, labellers, printing solutions and inspection systems. Automation makes it possible to have more stable, transparent, efficient and above all reliable processes throughout the line, particularly if at the same time there is an integrated transfer of all the process data. This article will shed light on the benefits that automation solutions offer, as well as the opportunities that are currently available in the area of product infeed and generally throughout the packaging process.

Today, packaging machines in the medical and pharmaceutical industries are generally a central component of an increasingly complex system solution, which is invariably complemented by customised conveyor and infeed systems, handling modules, labellers, printing solutions and inspection systems. Automation makes it possible to have more stable, transparent, efficient and above all reliable processes throughout the line, particularly if at the same time there is an integrated transfer of all the process data. This article will shed light on the benefits that automation solutions offer, as well as the opportunities that are currently available in the area of product infeed and generally throughout the packaging process.

Mehr erfahren

The digital challenge

One of the most important drivers for progress and development in the medical and pharmaceutical industries is digitalisation along the entire process chain. In order to benefit from digitalisation and the resulting added value, a clear digital strategy is essential and must be in harmony with the whole company strategy.

One of the most important drivers for progress and development in the medical and pharmaceutical industries is digitalisation along the entire process chain. In order to benefit from digitalisation and the resulting added value, a clear digital strategy is essential and must be in harmony with the whole company strategy.

Mehr erfahren

Digitalisation in the food industry

In many business sectors, digitalisation is already well advanced. However, the food processing industry is still in the early stages, although it is clear that digitalisation can make a major contribution to greater efficiency, process reliability, and transparency, as well as higher pack and product quality. The current situation is illustrated for us by Dr Marius Grathwohl, Vice President of Digital Products and Transformation at MULTIVAC.

In many business sectors, digitalisation is already well advanced. However, the food processing industry is still in the early stages, although it is clear that digitalisation can make a major contribution to greater efficiency, process reliability, and transparency, as well as higher pack and product quality. The current situation is illustrated for us by Dr Marius Grathwohl, Vice President of Digital Products and Transformation at MULTIVAC.

Mehr erfahren

“We are buying a solution”

The Dmitrovskie Group is Russia's oldest supplier of vegetable products for the domestic retail market. In recent years, the company has actively driven forward its vegetable processing business and expanded its range of pre-packed sliced vegetables, salads and cooked vegetable products.

The Dmitrovskie Group is Russia's oldest supplier of vegetable products for the domestic retail market. In recent years, the company has actively driven forward its vegetable processing business and expanded its range of pre-packed sliced vegetables, salads and cooked vegetable products.

Mehr erfahren

Turkey farm installs packaging line from MULTIVAC

No one knows better than Hayter’s Farm that a true Thanksgiving dinner is incomplete without a perfectly cooked stuffed turkey. For over 70 years, the family-run turkey farm, located in the town of Dashwood in the Canadian province of Ontario, has been dedicated to the sustainable growth of its business by adopting innovative rearing methods.

No one knows better than Hayter’s Farm that a true Thanksgiving dinner is incomplete without a perfectly cooked stuffed turkey. For over 70 years, the family-run turkey farm, located in the town of Dashwood in the Canadian province of Ontario, has been dedicated to the sustainable growth of its business by adopting innovative rearing methods.

Mehr erfahren

Innovative packaging concept contributes to the reduction in food waste

In Denmark as elsewhere, the awareness of sustainability has continued to rise in recent years. The responsible handling of resources also includes the prevention of food waste.

In Denmark as elsewhere, the awareness of sustainability has continued to rise in recent years. The responsible handling of resources also includes the prevention of food waste.

Mehr erfahren

Potato specialities securely packed and protected

Systematic quality assurance from the growing of the product to the cooking process and right through to packing - that is the quality claim of Peka Kroef. The Dutch producer of pre-cooked potato specialities used the opportunity presented by the replacement of some of his packaging machinery to further improve the reliability and security of his overall packaging process. In conjunction with MULTIVAC, a solution was devised, which meant a major step forward in terms of productivity, efficiency, and sustainability.

Systematic quality assurance from the growing of the product to the cooking process and right through to packing - that is the quality claim of Peka Kroef. The Dutch producer of pre-cooked potato specialities used the opportunity presented by the replacement of some of his packaging machinery to further improve the reliability and security of his overall packaging process. In conjunction with MULTIVAC, a solution was devised, which meant a major step forward in terms of productivity, efficiency, and sustainability.

Mehr erfahren

Sustainable packaging concept for fish specialities

For around 280 years Bond Seafood B.V, which is based in the Dutch city of Breda, has been inspiring the domestic and European market with its traditional fish specialities. The wide range of classic products is constantly being expanded with the addition of innovative specialities such as "Holland Sushi" and "Bruschetta" smoked mackerel fillets. However it is not only in its product range but also in terms of sustainability, that the family company shows itself as an innovator with a vision. It is for this reason that, in conjunction with MULTIVAC, the company developed a sustainable packaging concept. As one of the first fish processors in the country, Bond Seafood now uses recyclable mono materials for its packs.

For around 280 years Bond Seafood B.V, which is based in the Dutch city of Breda, has been inspiring the domestic and European market with its traditional fish specialities. The wide range of classic products is constantly being expanded with the addition of innovative specialities such as "Holland Sushi" and "Bruschetta" smoked mackerel fillets. However it is not only in its product range but also in terms of sustainability, that the family company shows itself as an innovator with a vision. It is for this reason that, in conjunction with MULTIVAC, the company developed a sustainable packaging concept. As one of the first fish processors in the country, Bond Seafood now uses recyclable mono materials for its packs.

Mehr erfahren

Technological leap with the MULTIVAC Centrifuge Feeder

Since it was founded more than 60 years ago, the Ecuadorian food manufacturer, PRONACA, has made it a mission to “feed the people well and promote the sustainable development of the agricultural sector.” The company systematically drives forward the expansion of its production sites and subsidiaries, as well as continuously expanding its product range - and it invests in state-of-the-art technology, so it can continue to increase the efficiency, cost-effectiveness and hygiene of its food production.

Since it was founded more than 60 years ago, the Ecuadorian food manufacturer, PRONACA, has made it a mission to “feed the people well and promote the sustainable development of the agricultural sector.” The company systematically drives forward the expansion of its production sites and subsidiaries, as well as continuously expanding its product range - and it invests in state-of-the-art technology, so it can continue to increase the efficiency, cost-effectiveness and hygiene of its food production.

Mehr erfahren

FRITSCH - A strong MULTIVAC brand

The integration of FRITSCH into the MULTIVAC Group is proceeding very rapidly. The joint CEOs, Andreas Eyd and Frank Gabriel, report in this interview on the current state and prospects of the family company, which was founded in 1926.

The integration of FRITSCH into the MULTIVAC Group is proceeding very rapidly. The joint CEOs, Andreas Eyd and Frank Gabriel, report in this interview on the current state and prospects of the family company, which was founded in 1926.

Mehr erfahren

Wine serving 4.0 – how a Belgian start-up company revolutionizes the hospitality industry

The trend in wine consumption in the hotel and restaurant sector is clearly moving towards serving wine by the glass. This gave a Belgian businessman and his two associates the opportunity to invent a completely new way of serving wine. The development of a suitable solution and new wine packaging proved to be highly ambitious. The inventors therefore turned to MULTIVAC for implementing a marketable and innovative solution.

The trend in wine consumption in the hotel and restaurant sector is clearly moving towards serving wine by the glass. This gave a Belgian businessman and his two associates the opportunity to invent a completely new way of serving wine. The development of a suitable solution and new wine packaging proved to be highly ambitious. The inventors therefore turned to MULTIVAC for implementing a marketable and innovative solution.

Mehr erfahren

Number of cycles doubled and the minimum of staff thanks to automated loading process

The increasing complexity of pharmaceutical products requires not only complicated pack designs but also packaging solutions, which enable such packs to be produced in a very effi cient and cost-effective way

The increasing complexity of pharmaceutical products requires not only complicated pack designs but also packaging solutions, which enable such packs to be produced in a very effi cient and cost-effective way

Mehr erfahren

Maximum flexibility in the portioning of fresh meat

Producers of sausage and meat products are being required, now more than ever, to provide a wide range of varieties for the market.

Producers of sausage and meat products are being required, now more than ever, to provide a wide range of varieties for the market.

Mehr erfahren

“Manufacturers of medical products should approach their suppliers at an early stage.”

Dr Jan Havel, Global Director for General Essential Modules (GEM), Biocompatibility, Sterilization and Packaging at TÜV SÜD Product Services GmbH explains, what manufacturers of medical products must take into consideration in the light of MDR.

Dr Jan Havel, Global Director for General Essential Modules (GEM), Biocompatibility, Sterilization and Packaging at TÜV SÜD Product Services GmbH explains, what manufacturers of medical products must take into consideration in the light of MDR.

Mehr erfahren

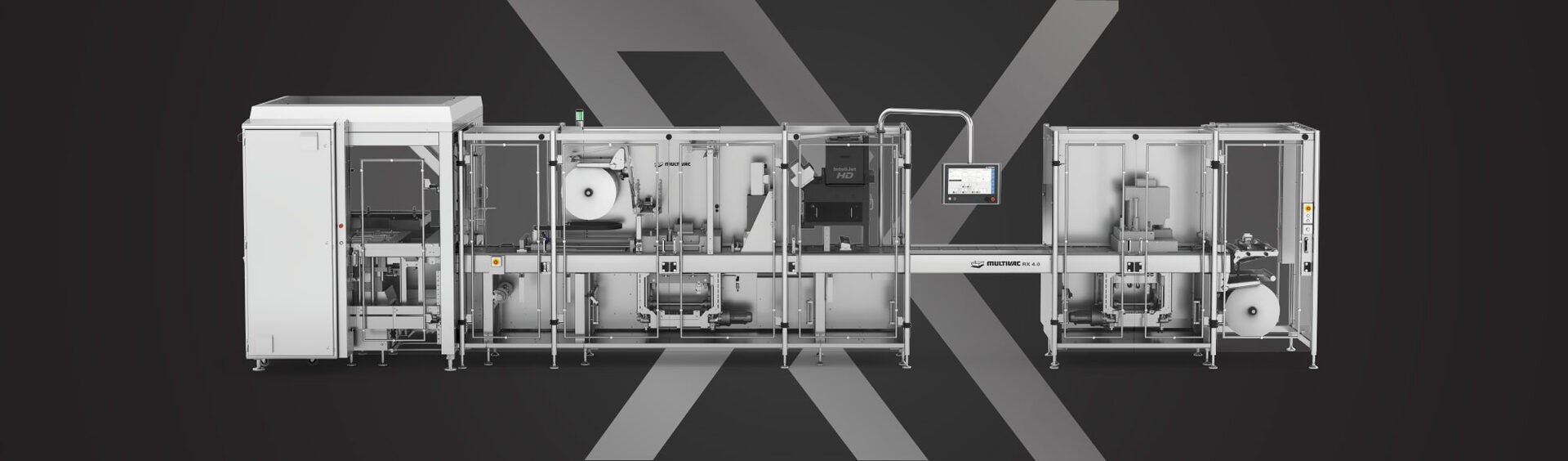

RX 4.0 offers maximum process reliability

The medical products and pharmaceutical industries place very great demands on the precision and reproducibility of processes when packing sensitive products - not least because of the new MDR and UDI regulations. The declared aims of both sectors also include improvements in throughput times, production efficiency and process flexibility.

The medical products and pharmaceutical industries place very great demands on the precision and reproducibility of processes when packing sensitive products - not least because of the new MDR and UDI regulations. The declared aims of both sectors also include improvements in throughput times, production efficiency and process flexibility.

Mehr erfahren

Process validation as the basis for maximum product safety

The relevance of process precision and reproducibility continues to increase in the medical products industry. Process validation provides seamless documentation, that the defined quality features are being achieved with a high level of reliability and consistency over the entire life cycle of the product. As a supplier of integrated solutions, MULTIVAC has many years of well-grounded expertise in all types of projects and packaging solutions. It can, therefore, offer professional support to manufacturers of medical devices, when they are implementing a challenging process validation.

The relevance of process precision and reproducibility continues to increase in the medical products industry. Process validation provides seamless documentation, that the defined quality features are being achieved with a high level of reliability and consistency over the entire life cycle of the product. As a supplier of integrated solutions, MULTIVAC has many years of well-grounded expertise in all types of projects and packaging solutions. It can, therefore, offer professional support to manufacturers of medical devices, when they are implementing a challenging process validation.

Mehr erfahren

Packaging flat sterile products efficiently and reliably

When flat and sterile disposable products are being packed in large batch sizes, it is not only the pack quality but also the efficiency and cost-effectiveness of production which is of great importance.

When flat and sterile disposable products are being packed in large batch sizes, it is not only the pack quality but also the efficiency and cost-effectiveness of production which is of great importance.

Mehr erfahren

Ter Beke uses digital solutions from MULTIVAC

The Belgian food company, Ter Beke, counts on digitalization – and on MULTIVAC – in its factory in Veurne. Thanks to MULTIVAC’s digital services, it has been possible to optimize the complex packaging processes for the different sausage varieties to a very significant degree – and within just the initial phase of development. Frequent factors in faults have been eliminated, and consequently the overall equipment efficiency has been increased.

The Belgian food company, Ter Beke, counts on digitalization – and on MULTIVAC – in its factory in Veurne. Thanks to MULTIVAC’s digital services, it has been possible to optimize the complex packaging processes for the different sausage varieties to a very significant degree – and within just the initial phase of development. Frequent factors in faults have been eliminated, and consequently the overall equipment efficiency has been increased.

Mehr erfahren

“Digitalisation in the packaging process is gaining in dynamism”

Interview with Dr Marius Grathwohl, Vice President of Digital Products & Transformation at MULTIVAC

Interview with Dr Marius Grathwohl, Vice President of Digital Products & Transformation at MULTIVAC

Mehr erfahren

Networked, reliable and efficient: a new dimension in tray packaging

Whether it is gourmet hamburgers, filled chicken breast, beef and poultry kebabs or even veggie kebabs, pork fillets or asparagus in bacon - quality, innovation and appetizing appearance are always the first priority at Premier Custom Foods. The ethos of the food producer based in Kansas City is to transform high-quality raw materials into innovative food products, to rethink the concept of taste, and to constantly surprise consumers with new ideas.

Whether it is gourmet hamburgers, filled chicken breast, beef and poultry kebabs or even veggie kebabs, pork fillets or asparagus in bacon - quality, innovation and appetizing appearance are always the first priority at Premier Custom Foods. The ethos of the food producer based in Kansas City is to transform high-quality raw materials into innovative food products, to rethink the concept of taste, and to constantly surprise consumers with new ideas.

Mehr erfahren

“60 years of MULTIVAC - Globalisation, digitalisation and sustainability”

Some 60 years after the company was founded, MULTIVAC has long been known as much more than just a producer of packaging machines. The company has now developed into a global systems supplier with an annual turnover of 1.2 billion euros. And it is treading new paths in digitalisation and sustainability. Discussion with Guido Spix, joint Group President of MULTIVAC.

Some 60 years after the company was founded, MULTIVAC has long been known as much more than just a producer of packaging machines. The company has now developed into a global systems supplier with an annual turnover of 1.2 billion euros. And it is treading new paths in digitalisation and sustainability. Discussion with Guido Spix, joint Group President of MULTIVAC.

Mehr erfahren

Successful collaboration

In the summer of 2020 Zandbergen World's Finest Meat successfully put two MULTIVAC lines into service in its new factory (The New Plant) in Zoeterwoude in the Netherlands, where Beyond Meat products are manufactured. The lines are complete with handling solutions as well as a labelling and marking system

In the summer of 2020 Zandbergen World's Finest Meat successfully put two MULTIVAC lines into service in its new factory (The New Plant) in Zoeterwoude in the Netherlands, where Beyond Meat products are manufactured. The lines are complete with handling solutions as well as a labelling and marking system

Mehr erfahren

Cheese production and the cloud

The traditional cheese manufacturer, Jermi Käsewerk, is modernising its production with MULTIVAC thermoforming packaging machines

The traditional cheese manufacturer, Jermi Käsewerk, is modernising its production with MULTIVAC thermoforming packaging machines

Mehr erfahren

This is how the Irish slice!

The meat company, Divilly Brothers, improves its production with a MULTIVAC slicer

The meat company, Divilly Brothers, improves its production with a MULTIVAC slicer

Mehr erfahren

“We support manufacturers of medical technology as a partner.”

Product safety, reliability, sustainability and cost-effectiveness: To implement the best possible packaging lines for manufacturers of medical technology, MULTIVAC continues to advance as a solution provider in line with the increasing requirements of the industry. In this interview, Luc van de Vel, Executive Vice President of the Food, Medical & Consumer Solutions Business Unit at MULTIVAC, explains what the future holds.

Product safety, reliability, sustainability and cost-effectiveness: To implement the best possible packaging lines for manufacturers of medical technology, MULTIVAC continues to advance as a solution provider in line with the increasing requirements of the industry. In this interview, Luc van de Vel, Executive Vice President of the Food, Medical & Consumer Solutions Business Unit at MULTIVAC, explains what the future holds.

Mehr erfahren

Sushi Mania - A bit of the Far East in Switzerland

Maximum efficiency, cost-effectiveness and pack appeal - with a big plus in terms of sustainability.

Maximum efficiency, cost-effectiveness and pack appeal - with a big plus in terms of sustainability.

Mehr erfahren

Less food wastage thanks to sustainable packaging and labelling concepts for fruit and vegetables

MULTIVAC adjusted to this trend at an early stage: Its solutions not only meet the sustainability requirements of customers, they also protect the packaged product perfectly, as well as reducing food wastage and appealing to retailers and consumers alike with their attractive design.

MULTIVAC adjusted to this trend at an early stage: Its solutions not only meet the sustainability requirements of customers, they also protect the packaged product perfectly, as well as reducing food wastage and appealing to retailers and consumers alike with their attractive design.

Mehr erfahren