Clean In Place MULTIVAC Hygienic Design

Clean In Place MULTIVAC Hygienic Design

Sanitary by Design

Food Safety Starts with Smarter Equipment

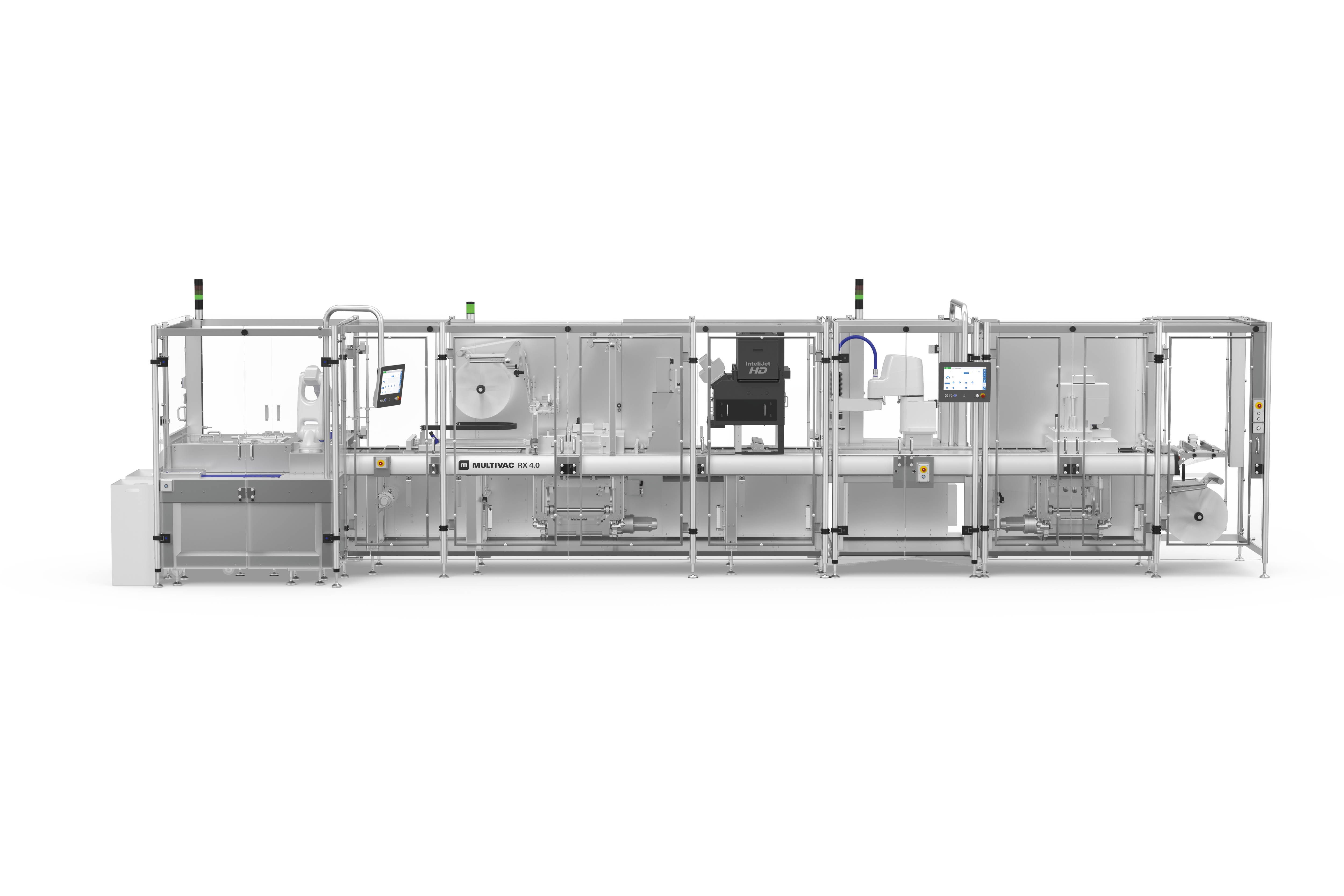

From slicers to packaging lines, MULTIVAC Group’s equipment is engineered for hygiene, helping processors meet food safety goals and reduce risk.

Smart Equipment Design

The U.S. Department of Agriculture’s (USDA) Food Safety and Inspection Service (FSIS) inspects over 161 million head of livestock, approximately 9.8 billion poultry carcasses, and 2.8 billion pounds of liquid, frozen, and dried egg products annually. From January 1, 2024, to February 12, 2025, the agency issued 59 recalls and public health alerts related to meat and poultry products. Consumer illness and injury can lead to recalls, plant shutdowns—sometimes permanently—loss of business, and long recovery periods. Despite rigorous efforts, food safety risks will always exist, and absolute safety is unattainable.

However, farmers, processors, suppliers, regulatory entities, government agencies, academia, and consumers must continue to prioritize food safety as their top objective.

Processor Perspective

Mississauga, Ontario-based Maple Leaf Foods is a 100-year-old, carbon neutral, meat and poultry processor in partnership with MULTIVAC Group. The company maintains a strong commitment to food safety with sanitation as the central focus of that commitment.

“First and foremost, effective and consistent execution of sanitation in all our processing facilities is foundational to meet our food safety mission every day,” said Steven Tsuyuki, Senior Director of Corporate Sanitation and EMP for Maple Leaf Foods. “We believe that there are shared values that can be realized when a strongly executed sanitation process is performed sustainably and preserves equipment assets.”

Maple Leaf understands the numerous steps and stakeholders involved with purchasing, installing and maintaining equipment that can be wet cleaned with effectiveness and efficiency. Sanitary design and water resiliency carry the same importance as performance and price when the company purchases equipment.

“Equipment design must adhere to the design principles specified in industry guidelines such as the Meat Institute Food Safety Equipment Design Principles Checklist and must be able to withstand repeated cycles of wet cleaning,” Tsuyuki said.

MULTIVAC Group was a member of the Food Safety Equipment Design Task Force that worked to develop these principles and MULTIVAC designs its equipment accordingly.

“MULTIVAC has been a strong collaborator with the Meat Institute, supporting the Advanced Listeria workshop and also supporting as a taskforce member in the development of the equipment sanitary design checklist,” Tsuyuki said.

Total cost of ownership is folded into sanitary design and water resiliency. Throughout long-term ownership of a piece of equipment, initially spending money on those two attributes provides a greater return on investment over time.

“Poor sanitary design raises the burden for wet cleaning and the need for frequent non-daily tasks such as deep cleaning and heat intervention,” Tsuyuki said. “Poor water resiliency causes frequent downtime at production startup, increases the cost to remediate recurring equipment damage due to water ingress or corrosion, and increases the cost of maintaining a plant component spares inventory (planning for failure).”

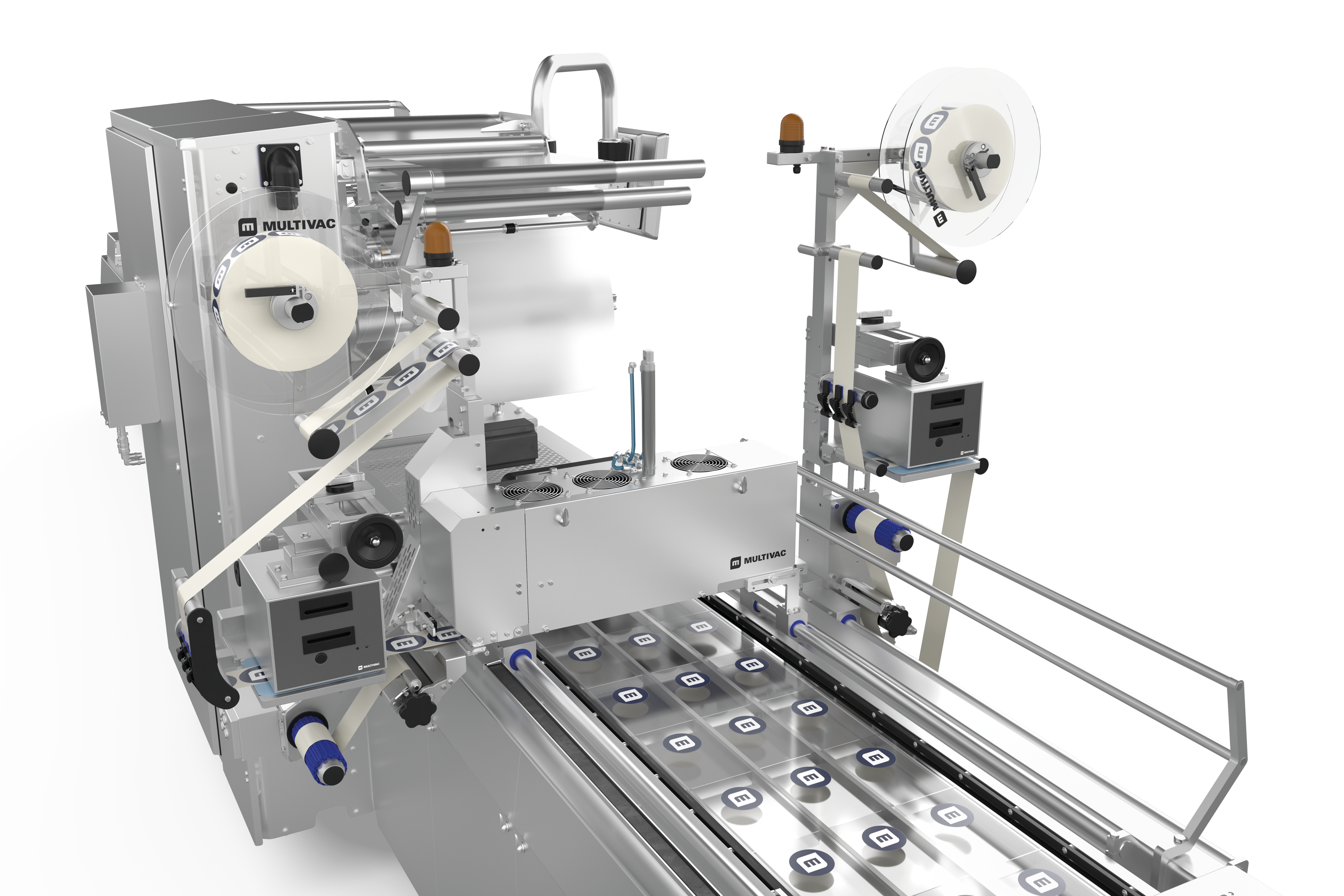

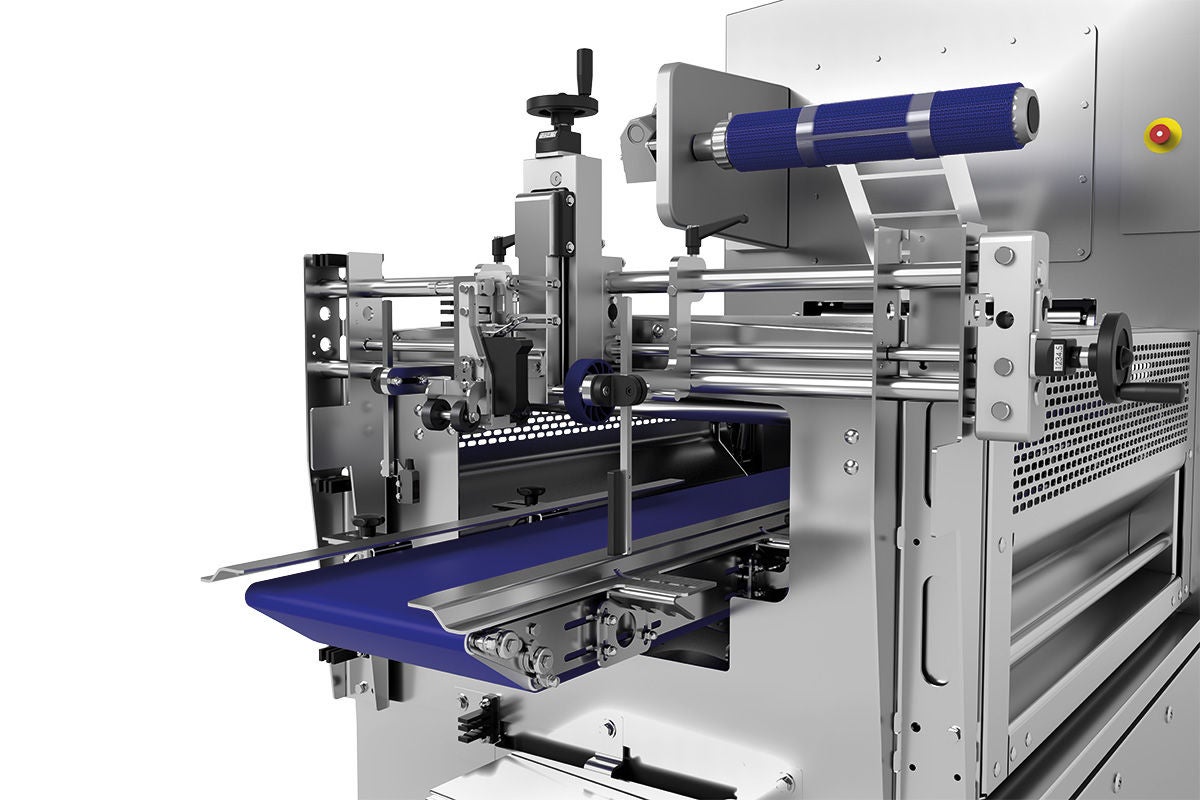

MULTIVAC Group’s move away from tube construction and toward open frame construction, allows wet-wash water to get rid of any hazards that could lead to colony producing units, rather than get stuck in hollow metal tubing, an environment with the potential to breed hazards.

The installation of equipment in the plant also plays an important role in its sanitation capabilities.

“Installing equipment in the plant must be performed in a manner that preserves the water resilient design of the purchased equipment,” Tsuyuki said. “Further, equipment must be verified to withstand both daily and non-daily cleaning tasks without damage or water ingress.”

Maple Leaf bases its sanitary on industry best practices. The company gathers performance data daily and compiles the results weekly at the plant level. It then compiles monthly results and scores all its processing facilities on a single scorecard and reports them across the entire organization.

“Sanitation performance is reviewed along with food safety, quality and health and safety metrics in a quarterly forum hosted by the COO and Chief Food Safety Officer,” Tsuyuki said.

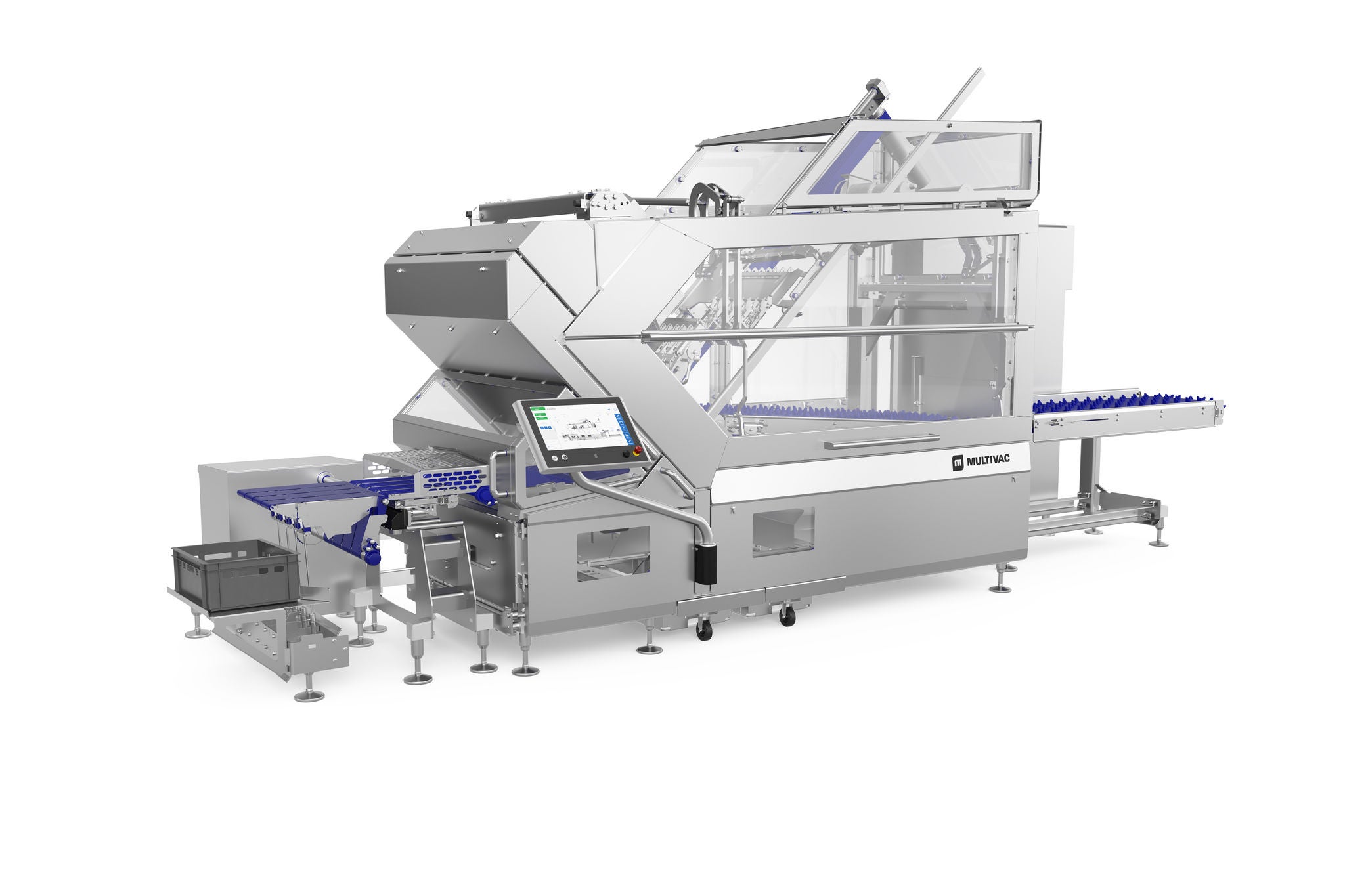

As technology evolves, so does meat processing equipment. Equipment manufacturers continuously take the advances in processing technology and customer feedback and leverage them to significantly improve their machines. Tsuyuki notes two different and important ways design and engineering have advanced equipment.

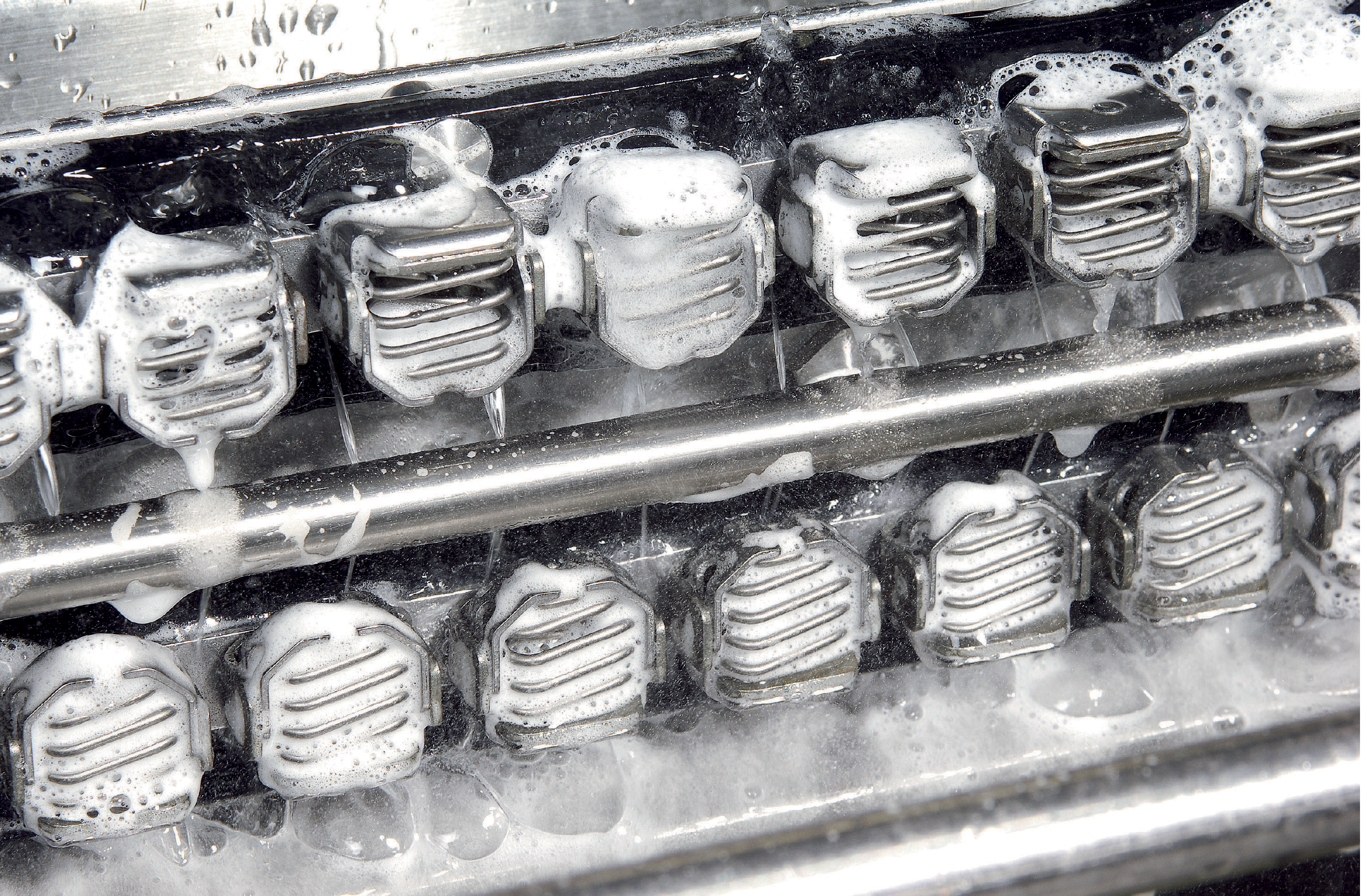

“Their efforts have made equipment easier to disassemble for wet cleaning without the need of tools and enabled access for cleaning of all surfaces where food soils accumulate and reduced growth niches (where food soils, water and bacteria can remain undisturbed in spite of wet cleaning).

“They’ve also improved component Resiliency,” he added. “Repeated cycles of wet cleaning create ‘wear and tear’ on equipment components that are in the direct ‘spray zone’ of the wet cleaning process. Recent design improvements protect vulnerable components from being directly sprayed on, improve enclosure design seals by reducing water ingress and condensation formation, utilize IP69K rated components where available, and reposition vulnerable components away from the spray zone all together.”

Tsuyuki added, “Multivac Group has been a strong Maple Leaf Foods collaborator for many years. The sanitary design of Multivac’s primary packaging machines has significantly improved our operations, greatly reducing the burden of cleaning through better equipment access, without the use of tools.”

The Drip, Drain, Draw Principle

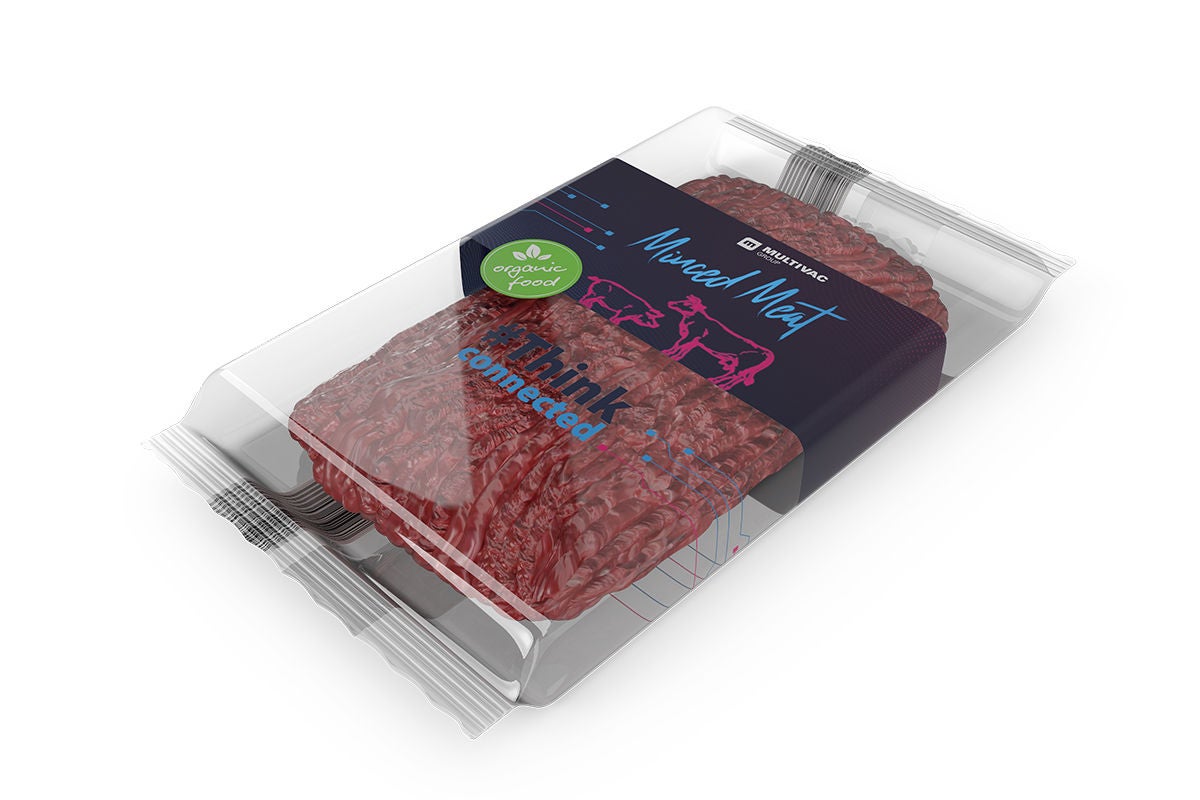

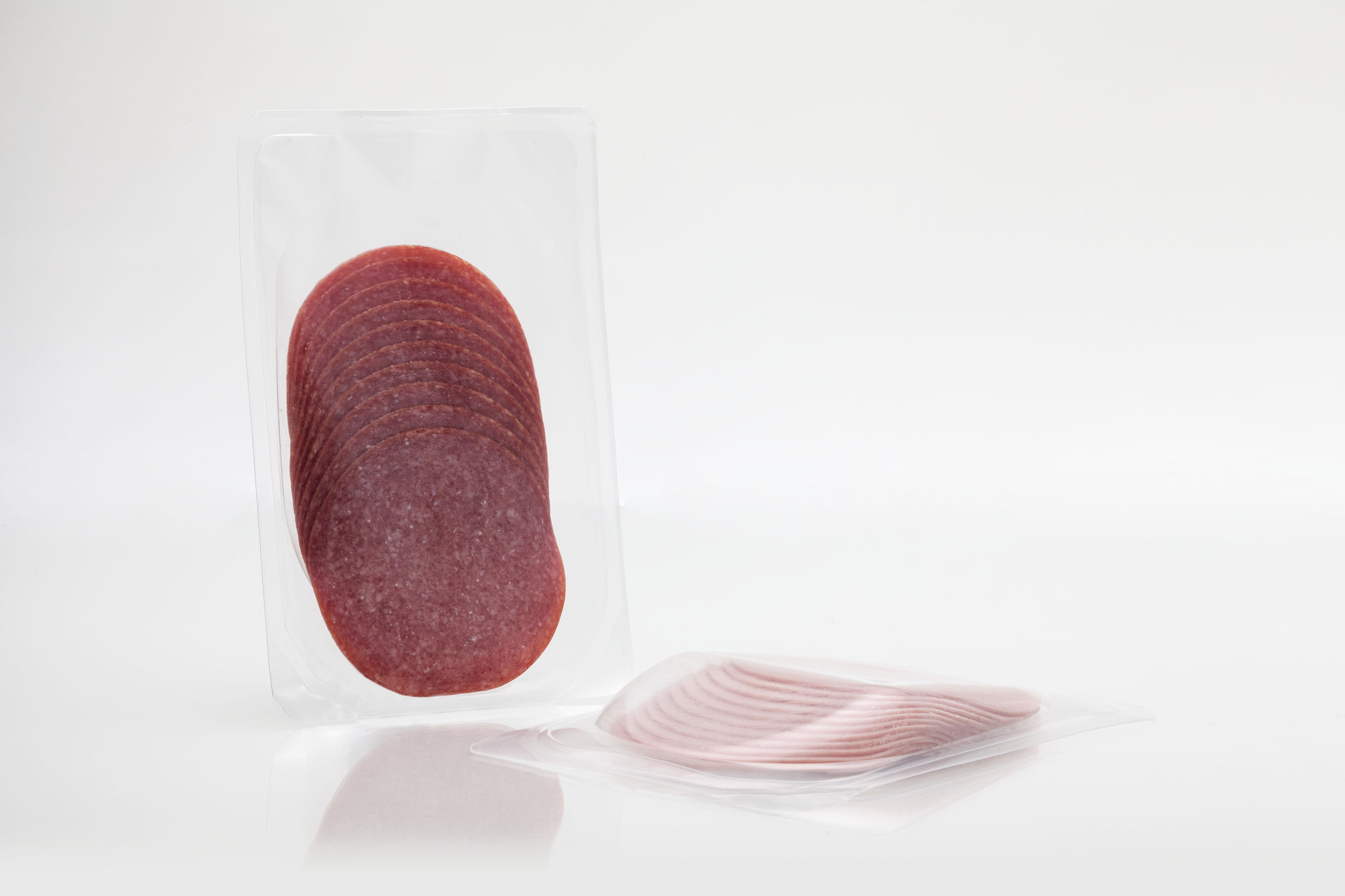

Once processors have slaughtered animals and carcasses are prepared for food production, the equipment used for transporting, portioning, slicing, and packaging must meet strict hygiene standards to ensure food safety. Machine design and construction play a critical role in maintaining these standards.

Christian Uebele, Director of Technical Product Management, Innovation, and Training at Kansas City, Mo.-based MULTIVAC Group, emphasizes that food safety in processing environments extends beyond direct food contact surfaces.

“From a design and engineering standpoint, you define a food contact surface by its ability to drip, drain, and draw,” he explains. “You have to consider where water droplets might fall, how gravity influences their movement, and whether they might land on food. This is the ‘drip and drain’ aspect. The ‘draw’ component refers to elements like conveyor belts that may collect and redistribute moisture, increasing contamination risks.”

To address these risks, equipment manufacturers must ensure surfaces are smooth to a microbiological standard of 0.8 μm Ra, allowing thorough cleaning. Additionally, machines must be constructed from FDA-approved food-safe materials, including plastics that comply with federal regulations.

“That ensures materials don’t dissolve in butter fats, degrade, or absorb moisture,” Uebele adds. “For example, a silicone gasket must not increase in weight due to moisture absorption.”

Other key design elements include:

- Eliminating inside corners by incorporating large radiuses to facilitate complete cleaning.

- Minimizing or eliminating mating surfaces through gasketing or design reduction.

- Avoiding external threads that can trap contaminants.

The Principles of Food Safety Design

Given the nature of food processing environments—including animal slaughter, microbiological contaminants, and the complexity of equipment—no machine is entirely immune to contamination. However, food safety design principles help mitigate risks.

“If a piece of equipment has a hard-to-clean spot, that doesn’t mean you discard it,” says Casey Gallimore, Senior Director of Regulatory Policy at the Meat Institute. “Instead, you assess the challenge and determine the next best option.”

Gallimore references the Food Safety Equipment Design Principles, developed by the Food Safety Equipment Design Task Force. This industry-wide initiative, involving leading processing and equipment manufacturers—including MULTIVAC Group—established a checklist for assessing equipment and identifying areas for improvement.

“The principles provide a great starting point for discussions between processors and equipment suppliers,” Gallimore explains. “They offer guidance on areas of concern and give suppliers insights for future equipment improvements. MULTIVAC Group, in particular, played a key role in updating these principles in 2021.”

The Importance of Strong Supplier-Processor Relationships

MULTIVAC Group prioritizes cleanability in its equipment design, incorporating features that facilitate sanitation. The company provides comprehensive manuals covering proper cleaning procedures and chemical recommendations.

“We design machines with ease of cleaning in mind,” Uebele says. “For example, we create mechanisms where guards can be propped up or attached in a way that allows for efficient cleaning in place.”

Gallimore stresses that both processors and equipment suppliers share responsibility for maintaining food safety. Processors must ensure their staff understands how to operate and clean new equipment, while suppliers must provide thorough instructions and support.

“Most companies now recognize the need to provide detailed cleaning instructions,” she notes. “If those don’t come with the equipment, processors should request them.”

The industry is increasingly fostering collaboration between sanitation companies and equipment suppliers, an encouraging development Gallimore has observed firsthand.

“At IPPE [2025], I saw some fantastic relationship-building efforts between sanitation teams and equipment manufacturers,” she says. “These conversations focus on real-world cleaning challenges and ways to improve equipment design for better sanitation.”

Continual Improvement in Equipment Design

MULTIVAC Group continuously refines its machines to enhance cleanability and ease of sanitation. The company transitioned from square tubing construction to open-frame designs in 1997, a shift the broader industry has since followed. Regular improvements, driven by food safety considerations, ensure ongoing advancements in machine sanitation.

“Our slicing equipment is an excellent example,” Uebele says. “We’ve developed an exceptionally clean machine, and we’re continuously refining its grippers and conveyors for even greater hygiene.”

Gallimore agrees that food safety innovations in equipment design have transformed the industry. Engineers and manufacturers proactively address contamination risks, leading to increased efficiency and cost savings for processors.

“The industry has fully embraced food safety as a core part of business strategy,” she says. “Today, it’s not just about how many hot dogs a machine can produce per hour, it’s also about the design principles ensuring that production happens in a food-safe manner.”

A critical component of food safety is ensuring that those responsible for cleaning and sanitation are well-trained and equipped for the task. However, processing facilities vary significantly in layout, chemical usage, water pressure, and space constraints, making sanitation a complex challenge.

While equipment design is subjective and tailored to different facilities, food safety remains a universal priority.

“Our goal is to build state-of-the-art equipment that meets and exceeds industry standards,” Uebele concludes. “Customers drive innovation and push for solutions beyond what’s considered standard. That ongoing demand for improvement is what drives our evolution.”

Latest news

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com