簡單到高度複雜的檢測解決方案

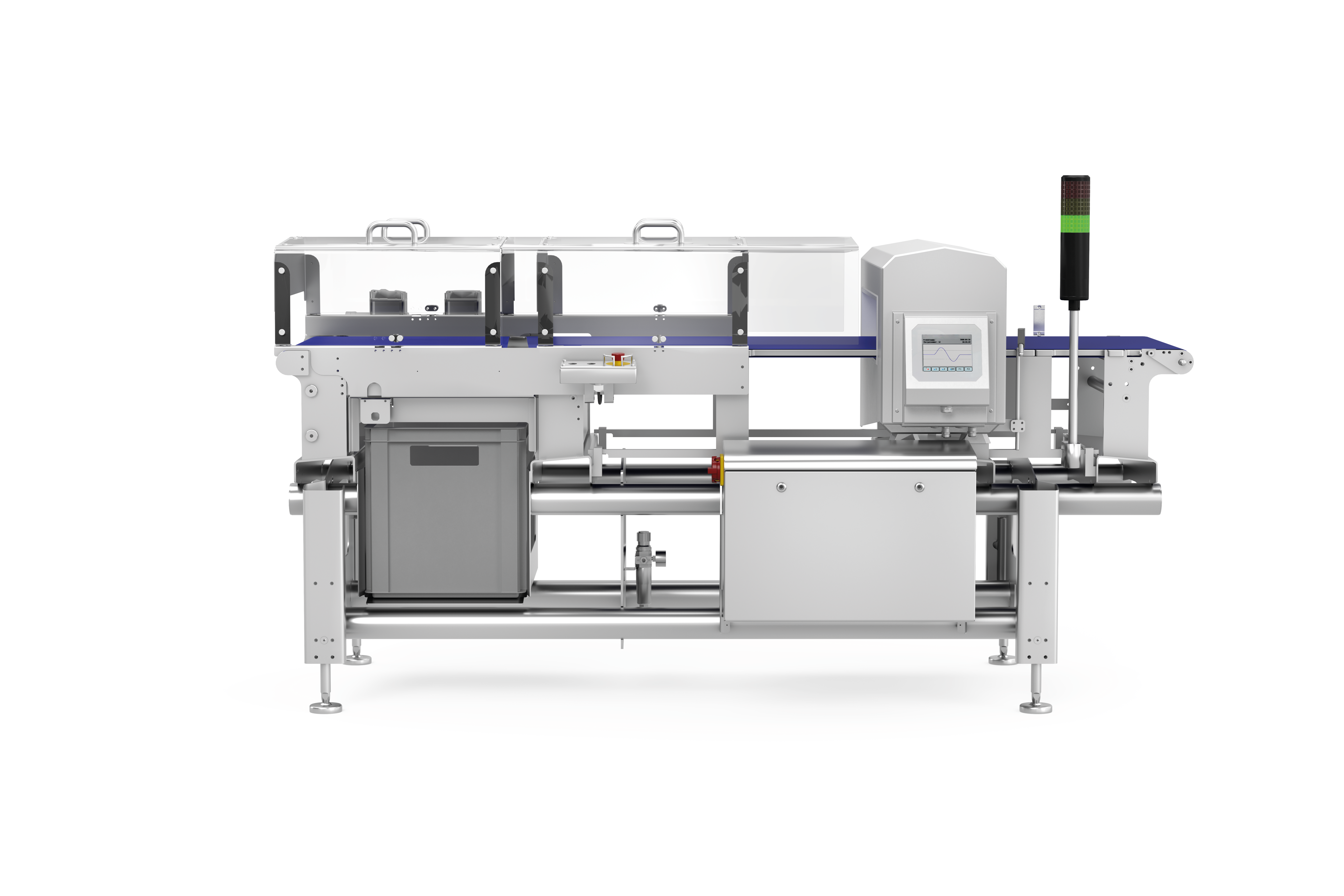

品質保障需要哪些檢測解決方案?我們的服務範圍從自動金屬和異物檢測,到高要求生產和包裝過程中的重量檢查和視覺檢測。所有我們的設備均按照高效、使用壽命長而設計,從而以最高精度和可重複性保證可靠的運行。我們會針對您提供個人化的建議,以便您找到可完美整合至生產和包裝線的合適解決方案。

提高產品安全性的創新檢測技術

我們的模組化解決方案可整合至一個單一的流程中,在生產和包裝安全方面無可比擬。主要原因是我們在不同檢測技術上避免了故障。通過標籤解決方案,可完美整合至包裝流程中或擴展附加功能。此外,我們也提供具有不同衛生標準的檢測設備。

成功案例

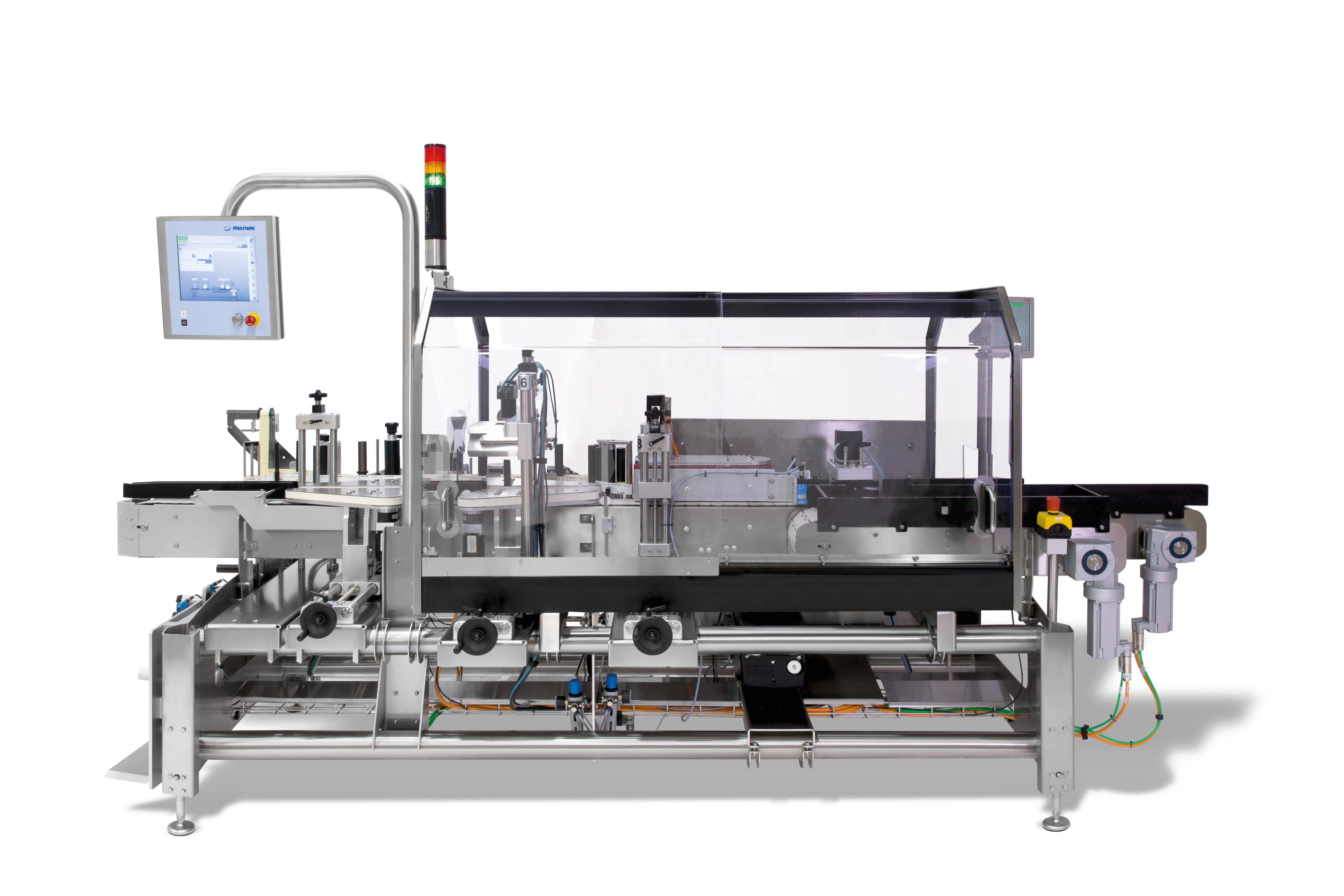

Reliable quality control

Thanks to visual inspection systems, quality control can be automated within the packaging procedure. These systems offer added value, particularly for food-processing businesses, since all the packs in a batch can be checked seamlessly instead of random sampling. Bell Schweiz AG with its headquarters in Basel is currently evaluating a pilot inspection system with a view to major investment. Pack aktuell* spoke to the person responsible for the project.

Thanks to visual inspection systems, quality control can be automated within the packaging procedure. These systems offer added value, particularly for food-processing businesses, since all the packs in a batch can be checked seamlessly instead of random sampling. Bell Schweiz AG with its headquarters in Basel is currently evaluating a pilot inspection system with a view to major investment. Pack aktuell* spoke to the person responsible for the project.

了解更多

Automated label and print inspection in the food industry

Rising demands in food labelling increase the complexity of information that has to be printed on labels. As the throughput of packaging lines continues to increase, it is no longer possible for the human eye to inspect label print thoroughly. Although present legislation does not yet stipulate the use of visual inspection systems for checking labels, investment in automatic inspection systems can be very beneficial for many reasons.

Rising demands in food labelling increase the complexity of information that has to be printed on labels. As the throughput of packaging lines continues to increase, it is no longer possible for the human eye to inspect label print thoroughly. Although present legislation does not yet stipulate the use of visual inspection systems for checking labels, investment in automatic inspection systems can be very beneficial for many reasons.

了解更多

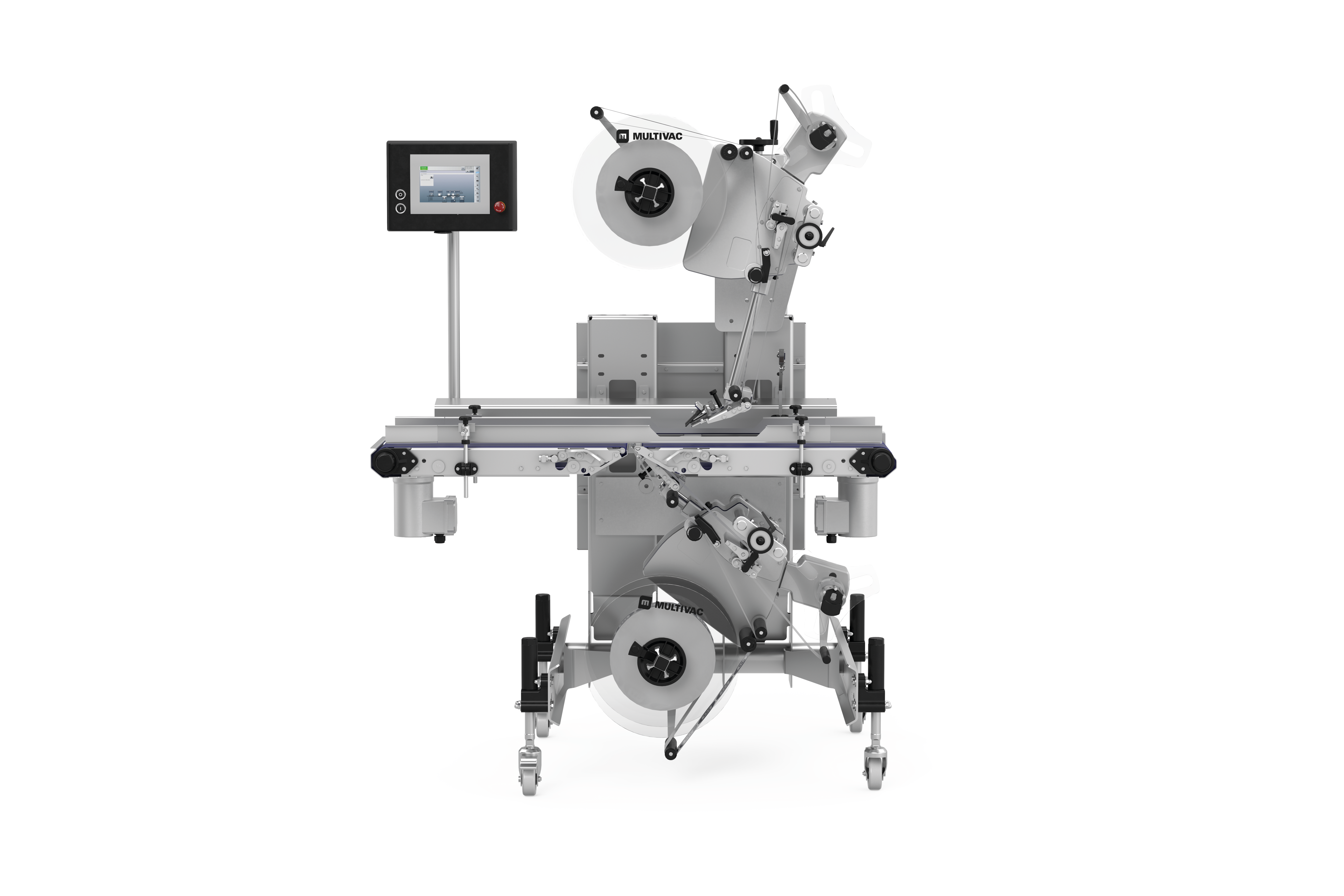

Success has a name

The modular conveyor belt labellers of the L 320 series from MULTIVAC Marking & Inspection offer the highest level of flexibility and precision in the labelling of cylindrical and oval products, shaped bottles, glasses and pots. Just such a model has recently been put into operation at Dr. August Wolff GmbH & Co. KG Arzneimittel for labelling the Linola products among others.

The modular conveyor belt labellers of the L 320 series from MULTIVAC Marking & Inspection offer the highest level of flexibility and precision in the labelling of cylindrical and oval products, shaped bottles, glasses and pots. Just such a model has recently been put into operation at Dr. August Wolff GmbH & Co. KG Arzneimittel for labelling the Linola products among others.

了解更多